AISC Verification Problem Example II.A-20

- Example

- Related

Problem Statement

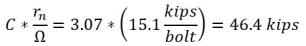

This document presents a comparative study between the published American Institute of Steel Construction (AISC) Design Examples Version 16.0 and the results generated by SDS2 version 2025.01 connection software for Example II.A-20. The central problem statement is to verify the available strength of an all-bolted singled plate shear splice of a beam-to-beam connection. This connection involves an ASTM A992 W24×68 beam and an ASTM A992 W24×55 beam with end reactions of RD = 10 kips and RL = 30 kips, using an ASTM A572 Grade 50 shear splice plate. The connection is shown in Figure 1.

Figure 1. Example II.A-20 elevation view

Connection design report output from SDS2 for this connection:

Note: To view the 3D model (U3D) of the structural joint in the PDF files, open the PDF using Bluebeam or Adobe Acrobat Reader.

Validation Method

The connection as shown in the AISC design example II.A-20 (see reference 1) was modeled in SDS2 and a connection design report was generated for both the ASD and LRFD design methods.

The core of this report features a comparison table for each connection limit state, showcasing the calculated capacities from both SDS2 and AISC. The order of the limit state table generally mirrors the sequence in which it was presented in the AISC example problem. This table also highlights the percent difference (% Δ) between these calculated values, providing a clear measure of any discrepancy, if any.

To further enhance understanding, this report includes relevant notes that discuss any differences or assumptions made during the calculation process. In certain cases where AISC did not calculate a connection capacity for a limit state, the connection capacity was back calculated based on the limit state values and documentation for this calculation is provided in the notes. The goal of this comparative study is to evaluate the precision and efficiency of the SDS2 connection design software in contrast to the AISC Design Examples and serves as a guide for better understanding and application of these two design calculations.

Comparison

Comparisons of the limit state checks are presented in Table 1 for ASD and Table 2 for LRFD. The limit state checks and calculated values aligned well between the published AISC Design Example document and the calculation generated by SDS2. The minor differences in calculated values, except where noted, were a result of rounding differences.

|

Table 1. Capacity comparison table for ASD |

||||

|

Limit state (ASD) |

SDS2 Capacity |

AISC Capacity |

%Δ |

Notes |

|---|---|---|---|---|

|

Bolt shear of web bolts |

16.2 kips / bolt |

16.2 kips / bolt |

0.0% |

|

|

Bolt bearing of web plate |

25.6 kips / bolt |

25.6 kips / bolt |

0.0% |

|

|

Bolt tearout of web plate at edge bolt |

15.1 kips / bolt |

15.1 kips / bolt |

0.0% |

|

|

Bolt tearout of web plate at non-edge bolt |

30.2 kips / bolt |

- |

- |

|

|

Coefficient for eccentrically load bolt group, C |

3.08 |

3.07 |

0.3% |

|

|

Bolt shear of web bolt group |

50.0 kips |

- |

- |

|

|

Bolt bearing on web plate |

49.1 kips |

46.4 kips |

5.5% |

|

|

Bolt bearing on W24x68 beam web |

50.0 kips |

- |

- |

|

|

Bolt bearing on W24x55 beam web |

50.0 kips |

- |

- |

|

|

Flexure yielding of web plate (limit state) |

404 kip-in |

404 kip-in |

0.0% |

|

|

Flexure yielding of web plate (shear capacity) |

162 kips |

162 kips |

0.0% |

|

|

Flexure rupture of web plate (limit state) |

293 kip-in |

293 kip-in |

0.0% |

|

|

Flexure rupture of web plate (shear capacity) |

117 kips |

117 kips |

0.0% |

|

|

Shear yielding of web plate |

90.0 kips |

90.0 kips |

0.0% |

|

|

Shear rupture of web plate |

58.5 kips |

58.5 kips |

0.0% |

|

|

Block shear rupture of web plate |

63.4 kips |

63.6 kips |

-0.3% |

|

|

Shear yielding of beam web |

186.4 kips |

- |

- |

|

|

Connection capacity |

49.1 kips |

46.4 kips |

5.5% |

|

|

Table 2. Capacity comparison table for LRFD |

||||

|

Limit state (LRFD) |

SDS2 Capacity |

AISC Capacity |

%Δ |

Notes |

|---|---|---|---|---|

|

Bolt shear of web bolts |

24.4 kips / bolt |

24.3 kips / bolt |

0.4% |

|

|

Bolt bearing of web plate |

38.4 kips / bolt |

38.4 kips / bolt |

0.0% |

|

|

Bolt tearout of web plate at edge bolt |

22.6 kips / bolt |

22.6 kips / bolt |

0.0% |

|

|

Bolt tearout of web plate at non-edge bolt |

45.2 kips / bolt |

- |

- |

|

|

Coefficient for eccentrically load bolt group, C |

3.08 |

3.07 |

0.3% |

|

|

Bolt shear of web bolt group |

75.0 kips |

- |

- |

|

|

Bolt bearing on web plate |

73.7 kips |

69.4 kips |

5.8% |

|

|

Bolt bearing on W24x68 beam web |

75.0 kips |

- |

- |

|

|

Bolt bearing on W24x55 beam web |

75.0 kips |

- |

- |

|

|

Flexure yielding of web plate (limit state) |

608 kip-in |

608 kip-in |

0.0% |

|

|

Flexure yielding of web plate (shear capacity) |

243 kips |

243 kips |

0.0% |

|

|

Flexure rupture of web plate (limit state) |

439 kip-in |

439 kip-in |

0.0% |

|

|

Flexure rupture of web plate (shear capacity) |

176 kips |

176 kips |

0.0% |

|

|

Shear yielding of web plate |

135.0 kips |

135.0 kips |

0.0% |

|

|

Shear rupture of web plate |

87.8 kips |

87.8 kips |

0.0% |

|

|

Block shear rupture of web plate |

95.1 kips |

95.2 kips |

-0.1% |

|

|

Shear yielding of beam web |

279.7 kips |

- |

- |

|

|

Connection capacity |

73.7 kips |

69.4 kips |

5.8% |

|

Table Notes

Note 1: AISC notes that edge bolts will conservatively be used for all the bolts.

Note 2: AISC does not calculate a capacity and notes that tearout controls over bearing and shear of bolts.

Note 3: The AISC capacity is not calculated directly in the example but is back calculated below. AISC uses the minimum bolt tearout capacity (and notes this is conservative) to design the bolts for tearout in this example. In other AISC examples, such as Ex. II.A-18

(pg. IIA-203) , when calculating the bolt group capacity with the instantaneous center of rotation method with C, AISC uses the average of the individual bolt capacities. SDS2 uses an average of individual bolt capacities considering the number of edge bolts and non-edge bolts across all connection types for consistency.

LRFD

ASD

AISC bolt group capacity:

AISC bolt group capacity:

Note 4: AISC notes that by inspection bearing and tearout on beam web will not govern.

Note 5: Both AISC and SDS2 calculate a moment capacity of 404 kip-in (ASD) or 608 kip-in (LRFD) which resolve into an equivalent shear load of 162 kips (ASD) or 243 kips (LRFD)

Note 6: Both AISC and SDS2 calculate a moment capacity of 293 kip-in (ASD) or 439 kip-in (LRFD) which resolve into an equivalent shear load of 117 kips (ASD) or 176 kips (LRFD) when accounting for the eccentricity.

References

-

AISC Committee on Manuals, Companion to the AISC Steel Construction Manual Volume 1: Design Examples, Version 16.0, American Institute of Steel Construction, 2023, https://www.aisc.org/publications/steel-construction-manual-resources/16th-ed-steel-construction-manual/manual-companion-for-16th-edition/.