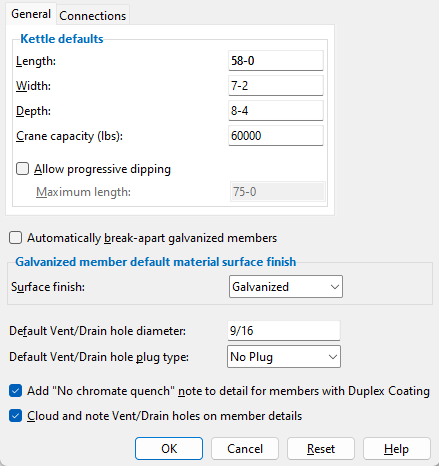

The Galvanizing Settings setup window ( Fabricator Settings )

| Settings on this window are read-only . They tell you how this window has been set up for this Fabricator in a full-featured SDS2 program . |

- The Galvanizing Check Tool , which this window does setup for, can be run in SDS2 Erector.

Also see :

- Galvanized (member edit window)

- Galvanizing Check Tool

- Surface finish (may be set to ' Galvanized ')

page 1 | contents | home > project settings > fabricator > detailing > | classic | top

------ Kettle size defaults ------

Length: The interior length (in the appropriate " Units ") of the galvanizing kettle. This information is referenced when the " ![]() Check for kettle fit " is run using the Galvanizing Check Tool and "

Check for kettle fit " is run using the Galvanizing Check Tool and " ![]() Allow progressive dipping " is off (not checked).

Allow progressive dipping " is off (not checked).

Note: If "

Allow progressive dipping " is on (checked), the AGA tool uses the " Maximum length " that is entered (below) when doing the "

Check for kettle fit ."

Parametrics: Fabricator().kettle_length

Width: The interior width (in the appropriate " Units ") of the galvanizing kettle. This information is referenced when the " ![]() Check for kettle fit " is run using the Galvanizing Check Tool .

Check for kettle fit " is run using the Galvanizing Check Tool .

Parametrics: Fabricator().kettle_width

Depth: The interior depth (in the appropriate " Units ") of the galvanizing kettle. This information is referenced when the " ![]() Check for kettle fit " is run using the Galvanizing Check Tool .

Check for kettle fit " is run using the Galvanizing Check Tool .

Parametrics: Fabricator().kettle_depth

Crane capacity (lbs): The maximum weight (in pounds) that the galvanizing crane can safely lift. This information is referenced when the " ![]() Check for kettle crane capacity " is run using the Galvanizing Check Tool .

Check for kettle crane capacity " is run using the Galvanizing Check Tool .

Parametrics: Fabricator().kettle_crane_capacity

Allow progressive dipping: ![]() or

or ![]() .

.

If this box is checked (

), the "

Check for kettle fit " that can be run using the Galvanizing Check Tool uses the distance that is entered as the " Maximum length " (below).

If the box is not checked (

), the "

Check for kettle fit " that can be run using the Galvanizing Check Tool uses the distance that is entered as the " Length " (above).

Parametrics: Fabricator().kettle_max_progressive_dip

Maximum length: The effective length of the galvanizing kettle (in the primary dimension " Units " or other units ) due to progressive dipping being allowed. This length might, for example, be approximately double the actual length of the interior of the kettle, since one procedure for progressive dipping is to galvanize half of the member, then galvanize the other half.

The "

Check for kettle fit " that can be run using the AGA tool uses this distance, instead of the actual " Length " of the kettle, when "

Allow progressive dipping " is on (checked).

Parametrics: Fabricator().kettle_max_progressive_dip

page 1 | contents | home > project settings > fabricator > detailing > | classic | top

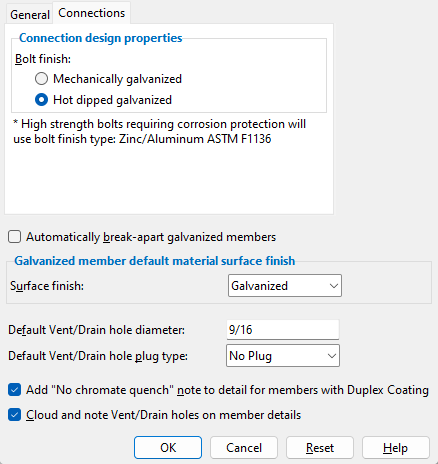

------ Connection design properties ------

Bolt finish: Mechanically galvanized or Hot dipped galvanized . This applies (in a full-featured SDS2 program ) when a member that has been set to be " ![]() Galvanized " undergoes Process and Create Solids .

Galvanized " undergoes Process and Create Solids .

If '

Mechanically galvanized ' is selected, the " Finish " of shop bolts and field bolts on " Galvanized " members will, by default, be set to ' Mechanically galvanized '.

If '

Hot dipped galvanized ' is selected, the " Finish " of shop bolts and field bolts on " Galvanized " members will, by default, be set to ' Hot dipped galvanized '.

page 1 | contents | home > project settings > fabricator > detailing > | classic | top

Automatically break-apart galvanized members: ![]() or

or ![]() .

.

If this box is checked (

), then checking the box for "

Galvanized " on a member window in a full-featured SDS2 program will also cause the box for "

Break apart " to be checked.

If the box is not checked (

), then checking the box for "

Galvanized " on a member window in a full-featured SDS2 program will not influence the state of the " Break apart " option.

Surface finish: Galvanized or Duplex coating .

' Galvanized ' sets the " Surface finish " to ' Galvanized ' on materials set to "

Galvanized "

' Duplex coating ' does the same as ' Galvanized ', except the " Surface finish " is ' Duplex Coating ', which is a special coating that allows galvanized steel to be painted.

Default vent/drain hole diameter: The diameter (a distance in the primary dimension " Units " or other units ) of vent/drain holes. On the Hole Edit window, this is the default " Hole diameter " when the " Hole type " is 'Vent/Drain '.

Default vent/drain hole plug type: No plug or Zinc plug or Plug weld or Aluminum or Epoxy . This is the " Plug type " of the vent/drain hole.

Add "No chromate quench" note to detail for duplex coated members: ![]() or

or ![]() . This applies (in a full-featured SDS2 program ) when a member that has been set to be "

. This applies (in a full-featured SDS2 program ) when a member that has been set to be " ![]() Galvanized " undergoes Process and Create Solids then undergoes auto detailing .

Galvanized " undergoes Process and Create Solids then undergoes auto detailing .

|

If this box is checked (

) and the proper steps (as described above) have been taken in a full-featured SDS2 program, a galvanizer note that reads " NO QUENCH - DUPLEX COATED " will be shown beneath the callout on a member detail.

If the box is not checked (

), the galvanizer note will not be shown under the callout.

Cloud and note Vent/Drain holes on member details: ![]() or

or ![]() . This applies when a member has submaterial with vent/drain holes. To get the note on the member detail, in a full-featured SDS2 program the member must have been set to "

. This applies when a member has submaterial with vent/drain holes. To get the note on the member detail, in a full-featured SDS2 program the member must have been set to " ![]() Galvanized " and have undergone auto detailing .

Galvanized " and have undergone auto detailing .

|

How vent/drain holes are called out on a member detail when this option is checked ( |

If this box is checked (

) and the above-mentioned steps are taken in a full-featured SDS2 program, the vent/drain holes will be clouded on the member detail and called out with a pointer to a label that reads "Vent/Drain Holes."

If the box is not checked (

), .the vent/drain holes will not be called out with a pointer to a label that reads "Vent/Drain Holes."

page 1 | contents | home > project settings > fabricator > detailing > | classic | top