Material Plate Washer Settings

- Step-By-Step

- Tips and Tricks

- Related Tools

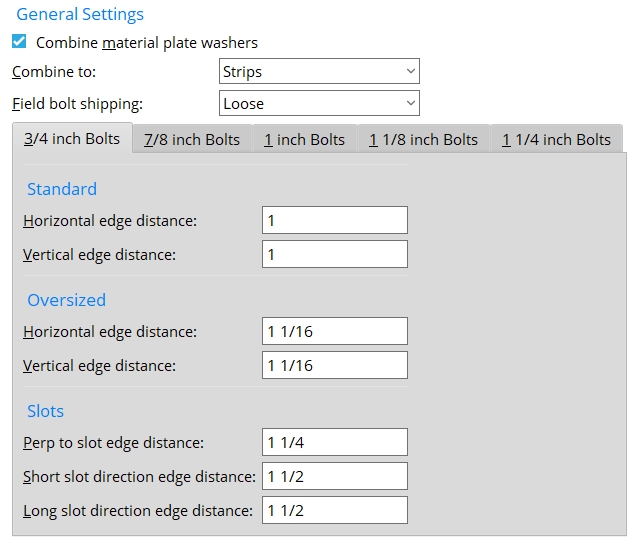

General Settings

Combine material plate washers: ![]() or

or ![]() . This option applies when bolts are generated for designed connections if Material Plate is set as the washer type for one or more situations (bolt types, etc.) specified at Home > Project Settings > Job > Bolts, Washers, and Holes > Washer Settings.

. This option applies when bolts are generated for designed connections if Material Plate is set as the washer type for one or more situations (bolt types, etc.) specified at Home > Project Settings > Job > Bolts, Washers, and Holes > Washer Settings.

|

When material plate washers are uncombined, each bolt gets a separate washer. |

If this box is checked (

), material plate washers for those bolts are combined into either strips or plates, depending on the choice made to Combine to.

If the box is not checked (

), material plate washers are not combined.

Override: Combine material plate washers on the Bolt Edit window lets you override -- for selected bolt groups -- the choice made here.

Combine to: Strips or Single Plate. This option applies when bolts are generated for connection designed connections if Material Plate is set as the washer type for one or more situations (bolt types, etc.) specified on the Washer Settings screen. Combine material plate washers must be checked ![]() )

)

|

|

Strips: Plate washers are combined to a strip per column of bolts.

Single Plate: Plate washers are combined into a single plate.

Override: Combine to on the Bolt Edit window lets you override -- for selected bolt groups -- the choice made here.

Field bolt shipping: Loose or With Member. This option applies when bolts are generated for connection designed connections if Material Plate is set as the washer type for one or more situations (bolt types, etc.) specified at Home > Project Settings > Job > Bolts, Washers, and Holes > Washer Settings.

Loose: Plate washers are created as one or more miscellaneous members. Plate washers for field bolts are not listed as submaterials of the member in the BOM, nor are they called out on the member detail.

With Member: Plate washers are created as submaterials of the member. Plate washers for both shop and field bolts are listed as submaterials of the member in the BOM, and are called out the member detail.

Also see: Field bolts listed on ... on the Bolt Detailing Settings screen determines which member the bolt is listed with when With Member is selected.

Standard & Oversized

|

hed = horizontal edge distance |

Horizontal edge distance: The horizontal distance from the nearest width edge of the material plate washer to the center of the nearest hole.

Vertical edge distance: The vertical distance from the nearest length edge of the material plate to the center of the nearest hole.

Slots

|

ssded = short slot direction edge distance |

Perp to slot edge distance: The distance measured perpendicular with the slot from the center of the nearest short slot or long slot to the length edge of the material plate washer.

Short slot direction edge distance: The distance measured parallel with the slot from the center of the nearest short slot to the width edge of the material plate washer.

Long slot direction edge distance: The distance measured parallel with the slot from the center of the nearest long slot to the width edge of the material plate washer.

|

|

OK (or the Enter key) closes this screen and applies the settings.

Cancel (or the Esc key) closes this screen without saving any changes.

Reset undoes all changes made to this screen since you first opened it. The screen remains open.