The Plate Design Settings window ( Job Settings )

| Settings on this window are read-only . They tell you how this window has been set up for this Job in a full-featured SDS2 program . |

Also see :

- Process and Create Solids (selections here applied during)

- Moment connections (most selections on this window apply to)

page 1 | contents | home > project settings > job > design > | classic

To open Plate Design Settings :

Method 1 : Home > Project Settings > Job > Design > Plate Design Settings .

Method 2 : In Modeling or the Drawing Editor , choose Settings > Job Settings > Plate Design Settings (classic), or use a keyboard shortcut , or click the icon.

page 1 | contents | home > project settings > job > design > | classic | top

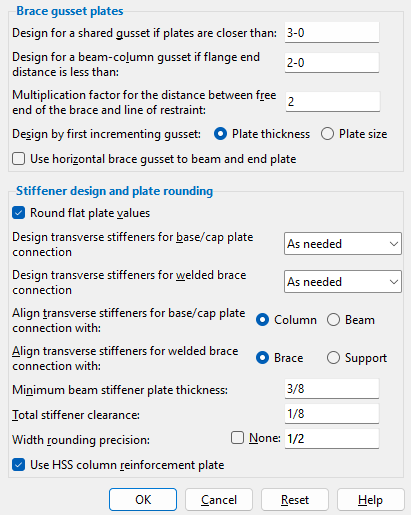

------ Brace gusset plates ------

Design for shared gusset if plates are closer than: Any distance (from 0 to 4-0 feet ' Imperial ' or 0 to 1219 mm ' Metric '). For all types of bracing, this is approximately the distance between the points where the work line of each brace intersects the surface that the gusset attaches to. If the distance shown here is greater than connection design projects two gusset plates to be apart from one another, then a full-featured SDS2 program will design a shared gusset plate.

Design for a beam-column gusset if flange end distance is less than: The distance (in the primary dimension " Units " or in other units ) from the point where the work line of the vertical brace intersects the beam flange to the face of the column. This distance is measured parallel with the beam workline.

|

| In the example on the left, the actual flange end distance in the model is less than setup value ( x ), and therefore a beam-column gusset is designed. |

|

A beam-column gusset for a vertical brace to a column web. The distance entered here, in Plate Design Settings , also applies to the design of such a gusset plate. |

Effect on a full-featured SDS2 program: This setting may be used to prevent a full-featured SDS2 program from designing gusset plates that are too long. If a vertical brace in Modeling is closer to the column than the distance entered here, the program designs a beam-column gusset. If the brace is farther from the column than this distance, the program designs a gusset for the beam only.

Multiplication factor for the distance between the end of the brace and line of restraint: Any whole number from 0 to 10 . To a beam & column, the vertical brace can be angle or WT ( stem vertical ) or wide flange or HSS . To a beam only , the vertical brace can be angle or star angle or channel or WT ( vertical , horizontal ) or HSS or wide flange. To a column only , the vertical brace can be angle or channel or WT (vertical, horizontal) or HSS or wide flange. To a column base/cap plate , the vertical brace can be WT (stem vertical) or HSS or wide flange.

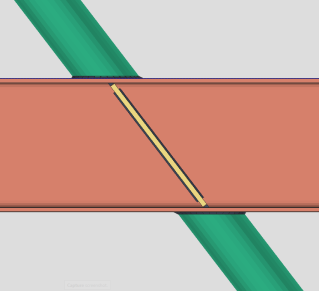

factor = 1 |

factor = 3 |

| The construction lines in these examples are the separated by a distance equal to the thickness of the gusset plate. | |

During connection design of a seismic connection, a full-featured SDS2 program multiplies the ' number ' entered here by the thickness of the gusset plate to set the distance measured parallel with the brace workline from the end of the brace (or paddle plate or built-up tee) to the nearest corner of the gusset plate. Special cases: If the " Pipe/tube end-fitting " is ' Bolted ' or ' Paddle plate ', the distance is measured from the end of the built-up tee or paddle plate to the line of restraint.

Definition: The "line of restraint" is the plastic hinge location on the brace line. In is a line perpendicular to the brace workline that is drawn through whichever corner of the gusset is nearest to the end of the brace (or paddle plate or built-up tee).

Design by first incrementing gusset: Plate thickness or Plate size . This applies when gusset plates undergo connection design in a full-featured SDS2 program .

If ' Plate thickness ' is selected, the program first adjusts the gusset plate's thickness in order to design a gusset plate that stands up to the load. The gusset plates will generally be thicker and smaller.

If ' Plate size ' is selected, the program first adjusts the plate's size in order to design a gusset plate that stands up to loads. The gusset plates will generally be thinner but larger in size.

Use horizontal brace gusset to beam and end plate: ![]() or

or ![]() . This applies when the " Connection design method " is ' EUROCODE 3 ' or ' EUROCODE 3 UK '.

. This applies when the " Connection design method " is ' EUROCODE 3 ' or ' EUROCODE 3 UK '.

|

|

If this box is checked (

), connection design in a full-featured SDS2 program is permitted to weld the horizontal brace gusset plate to the end plate.

If the box is not checked (

), connection design is not permitted to weld the horizontal brace gusset plate to the end plate. In the example above, this results in a connection failure with the message " Gusset interferes with beam connection ."

page 1 | contents | home > project settings > job > design > | classic | top

------ Stiffener design and plate rounding ------

Round flat plate values: ![]() or

or ![]() . This option applies to Create Solids in a full-featured SDS2 program .

. This option applies to Create Solids in a full-featured SDS2 program .

If this box is checked (

), the program rounds up the length, width and thickness of plates to the Home > Project Settings > Fabricator > Detailing > Drawing Presentation > the " Primary Dimensions " tab > " Dimension precision ." The actual dimensions of all system-generated flat plates in the 3D model will match the dimensions in the bill of material and the dimensions shown on details.

If the box is not checked (

), plates are dimensioned on member and submaterial details and called out in the bill of material per the the " Dimension precision ." However, the actual dimensions of system-designed plates in the 3D model is determined by connection design.

Design transverse stiffeners for base/cap plate connection: As needed , Always , or Never . This applies when " Use transverse beam stiffener " is set to ' Automatic ' in a Column Edit window's " ![]() Connection specifications " for a user base/cap plate or auto base/cap plate to a beam flange. The " Use transverse beam stiffener " connection specification is also available at Home > Project Settings > Job > Connections > Auto Standard Connections and Home > Project Settings > Job > Connections > User Defined Connections . Transverse beam stiffeners can be designed when a column with an auto or user base/cap plate frames to the top or bottom flange of a beam.

Connection specifications " for a user base/cap plate or auto base/cap plate to a beam flange. The " Use transverse beam stiffener " connection specification is also available at Home > Project Settings > Job > Connections > Auto Standard Connections and Home > Project Settings > Job > Connections > User Defined Connections . Transverse beam stiffeners can be designed when a column with an auto or user base/cap plate frames to the top or bottom flange of a beam.

|

|

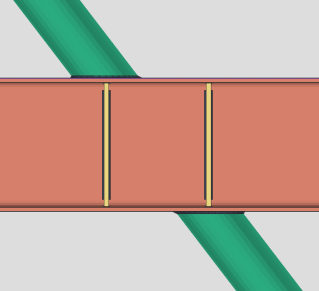

' As needed ' instructs connection design to create one pair of full-depth transverse beam stiffeners (one on the beam's near side, one far side), when the " Load is large enough that the supporting wide flange beam's web capacity is exceeded and stiffeners are required." Two pairs of stiffeners are created when the " Load " is sufficiently large. The two pairs of stiffeners align with the flanges of the column. A single pair of stiffeners is centered with respect to the column work line.

' Always ' instructs connection design to create at least one pair of full-depth transverse beam stiffeners (one on the beam's near side, one far side), regardless of the " Load ." Two pairs of stiffeners are created when the " Load " is sufficiently large. The two pairs of stiffeners align with the flanges of the column. A single pair of stiffeners is centered with respect to the column work line.

' Never ' instructs connection design to not create full-depth transverse beam stiffeners, even if they are required by connection design. A red banner will appear in "

Information " that reads "Beam web design checks removed by user". This message will also appear in the column's design calculation.

Also see: " Minimum beam stiffener plate thickness ."

Design transverse stiffeners for welded brace connection: As needed , Always , or Never . This applies when " Use transverse support stiffener " is set to ' Automatic ' in a Vertical Brace Edit window's " ![]() Connection specifications " for a Welded connection to a wide flange beam, column, or vertical brace flange. The stiffener plates will be located on the supporting wide flange member to stiffen the member's web.

Connection specifications " for a Welded connection to a wide flange beam, column, or vertical brace flange. The stiffener plates will be located on the supporting wide flange member to stiffen the member's web.

' As needed ' instructs connection design to create full-depth transverse stiffeners in this situation only if the vertical brace's " Load " is large enough that the supporting wide flange member's web capacity is exceeded and stiffeners are required.

' Always ' instructs connection design to always create full-depth transverse stiffeners, even if they are not required by connection design.

' Never ' instructs connection design to not create full-depth transverse stiffeners, even if they are required by connection design. A red banner will appear in "

Information " that reads "Supporting member web/flange design checks removed by user". A similar message will appear in the vertical brace's design calculation.

Align transverse stiffeners for base/cap plate connection with: Column or Beam . The choice made here applies to connection design , which takes place in a full-featured SDS2 program . It applies when transverse beam stiffeners are designed for an auto base/cap plate or user base/cap plate that bolts to the flange of a beam.

|

|

If ' Column ' is selected here and ' Automatic ' is selected for " Align stiffeners with " on a user or auto base cap/plate, the full-featured SDS2 program designs transverse beam stiffeners that are parallel with the work line of the column.

If ' Beam ' is selected here and ' Automatic ' is selected for " Align stiffeners with " on a user or auto base/cap plate, the program designs transverse beam stiffeners that are perpendicular to the workline of the beam.

Related setup options: " Design transverse stiffeners for base/cap plate connection " ( Plate Design Settings ), " Minimum beam stiffener plate thickness " ( Plate Design Settings ), " Total stiffener clearance " ( Plate Design Settings ).

Align transverse stiffeners for welded brace connection with: Brace or Support . This applies when " Align stiffeners with " is set to ' Automatic ' in a Vertical Brace Edit window's " ![]() Connection specifications " for a Welded connection to a wide flange beam, column, or vertical brace flange.

Connection specifications " for a Welded connection to a wide flange beam, column, or vertical brace flange.

|

|

' Brace ' aligns the stiffeners with the geometry of the vertical brace.

' Support ' aligns the stiffeners perpendicular to the supporting wide flange member's flanges.

Minimum beam stiffener plate thickness: A distance (in the primary dimension " Units " or in other units ). Connection design in a full-featured SDS2 program creates beam stiffener plates on a beam (placed over or under a column) that are as thick or thicker than the thickness shown here. The number of stiffeners depends on the " Load " on the column.

Also see: " Design transverse stiffeners for base/cap plate connection "

Total stiffener clearance: A distance (in the primary dimension " Units " or in other units ). The clearance at each end of a stiffener is 1/2 of the "total clearance" that is entered here. ' 0 ' makes the stiffener flush to the surface. Some edges of stiffeners are always flush (no matter what distance is entered here). The table below lists clearances that are governed by the entry made here.

| Stiffener Type | Clearance |

| Full depth beam stiffeners over/under columns. | The top/bottom stiffener edge to the inside of the beam's top/bottom flange. |

| Extended shear plate to column web. | Each edge of stability plate to inside column flanges. |

| Shear plate with stiffener opposite. | Bottom edge of stiffener to inside of the beam's bottom flange. |

| Full depth extended tee for a clip angle , bent plate or end plate connection. | Bottom edges of both built-up tee plates to the inside of the beam's bottom flange. |

|

The clearance at each end of the stiffener is 1/2 of the " Total stiffener clearance " that is entered here, in setup. |

Also see: " Total stiffener clearance " on the Moment Plate Design Settings window provides similar control of clearances on moment stiffeners.

Width rounding precision: The distance (in the primary dimension " Units " or other units ) that is the precision to which connection design is instructed to round the width of the stiffener.

|

| The stiffener width in the left example is 3 1/8 inch. The example on the right has a 3-inch plate width. |

Connection design in a full-featured SDS2 program creates transverse beam stiffeners whose interior width edge is flush with the web of the beam and whose exterior width edge is as close as the " Width rounding precision " permits to the outer edge of the flange of the beam. In the left example above, a " Width rounding precision " of ' 1/8 ' permits the outer edge of the stiffener to align with the outside of the beam's flanges. In the above, right example, a " Width rounding precision " of ' 1/2 ' creates a narrower stiffener whose outer edge is 1/8 inch inside of the outer edge of the beam's flange.

Transverse beam stiffeners can be designed in a full-featured SDS2 program when a column with an auto or user base/cap plate frames to the top or bottom flange of a beam. For an auto base/cap plate, "

Use transverse beam stiffener " instructs connection design to create transverse stiffeners. For a user base/cap plate, "

Use transverse beam stiffener " instructs the program to create the stiffeners.

Related setup options: " Design transverse stiffeners for base/cap plate connection " ( Plate Design Settings ), " Minimum beam stiffener plate thickness " ( Plate Design Settings ), " Total stiffener clearance " ( Plate Design Settings ).

Connection design lock: " Plate width " (in the " Stiffener plate " leaf).

Use HSS column reinforcement plate: ![]() or

or ![]() . This applies to single-plate shear connections (" Material type " = ' Plate ') and welded moment connections (" Moment type " = ' Welded ' ) and to vertical brace gusset plates when that connection frames to an HSS rectangular (or tube) column with a thin wall. This may apply to beam connections when " Use HSS column reinforcement plate " is set to ' Automatic '. It may apply to vertical brace connections when " Use HSS column reinforcement plate " is set to ' Automatic '.

. This applies to single-plate shear connections (" Material type " = ' Plate ') and welded moment connections (" Moment type " = ' Welded ' ) and to vertical brace gusset plates when that connection frames to an HSS rectangular (or tube) column with a thin wall. This may apply to beam connections when " Use HSS column reinforcement plate " is set to ' Automatic '. It may apply to vertical brace connections when " Use HSS column reinforcement plate " is set to ' Automatic '.

|

|

|

If this box is checked (

) and " Use HSS column reinforcement plate " and/or " Use HSS column reinforcement plate " is set to ' Automatic ', connection design in a full-featured SDS2 program is instructed to weld a reinforcement plate to the face of the HSS rectangular column if such a reinforcement plate is needed to avoid a connection design failure. The single-plate shear connection or welded moment connection or vertical brace gusset plate will weld to the reinforcement plate.

If the box is not checked (

) and ' Automatic ' is set as previously mentioned, connection design in a full-featured SDS2 program is instructed to not create an HSS column reinforcement plate. A beam connection may fail with the message " Slender col wall - not valid for a shear tab conn ." A vertical brace gusset plate connection may fail with the message " HSS wall strength fails ."

Connection specifications (beam): Use HSS column reinforcement plate

Connection failure message (beam): Slender col wall - not valid for a shear tab conn

Connection specifications (vertical brace): Use HSS column reinforcement plate

Connection failure message (vertical brace): HSS wall strength fails

Connection design locks (on column): Column Reinf Plate

page 1 | contents | home > project settings > job > design > | classic | top