The Design Settings setup window ( Job Settings ) (read-only)

Also see :

- Connection design (choices made to Design Settings are applied during)

- Design Calculations and Expanded Calculations (affected by settings on this window)

- Composite Design (to apply composite design choices in a full-featured SDS2 program )

- Composite Reaction Factors (related setup for composite design)

home > project settings > job > design > | classic | top

Method 1 : Home > Project Settings > Job > Design > Design Settings .

Methods 2, 3 & 4 : In Modeling or the Drawing Editor , choose Settings > Job Settings > Design Settings (classic), or use a keyboard shortcut , or click the icon.

home > project settings > job > design > | classic | top

|

|

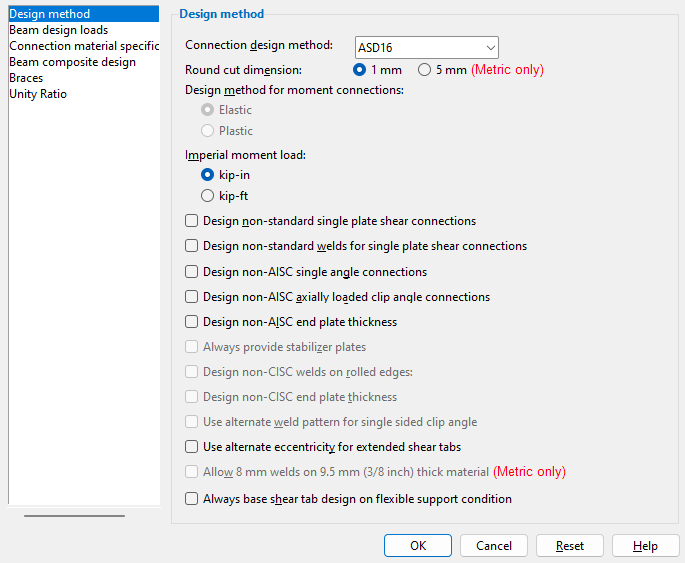

------ Design method ------

Connection design method: ASD 16 or ASD 15 or ASD 14 or ASD 13 or ASD 9 or LRFD 16 or LRFD 15 or LRFD 14 or LRFD 13 or LRFD 3 or CISC 12 or CISC 11 or CISC 10 or CISC 9 or CISC 8 or EUROCODE 3 or EUROCODE 3 UK or CHINA GB50017-2003 or INDIA IS800-2007 .The selection made here affects connection design , during which connections are designed per the selected connection design code. The Connection Calculation Cover Sheet is a print-out of the formulas used for the selected method of connection design.The following buttons open a setup window for the selected design method:

Method Design Specifications ' ASD 16 ' AISC Steel Construction Manual,

Sixteenth Edition' ASD 15 ' AISC Steel Construction Manual,

Fifteenth Edition' ASD 14 ' AISC Steel Construction Manual,

Fourteenth Edition' ASD 13 ' AISC Steel Construction Manual,

Thirteenth Edition' ASD 9 ' AISC Manual of Steel Construction, Allowable Stress Design, 9th Edition ' LRFD 16 ' AISC Steel Construction Manual,

Sixteenth Edition' LRFD 15 ' AISC Steel Construction Manual,

Fifteenth Edition' LRFD 14 ' AISC Steel Construction Manual,

Fourteenth Edition' LRFD 13 ' AISC Steel Construction Manual,

Thirteenth Edition' LRFD 3 ' Manual of Steel Construction, Load and Resistance Factor Design, 3rd Edition ' CISC 12 ' CISC Handbook of Steel Construction,

Twelfth Edition' CISC 11 ' CISC Handbook of Steel Construction,

Eleventh Edition' CISC 10 ' CISC Handbook of Steel Construction,

Tenth Edition' CISC 9 ' CISC Handbook of Steel Construction,

Ninth Edition' CISC 8 ' CISC Handbook of Steel Construction,

Eighth Edition' AS 4100 ' Standard for Steel Structures, AS4100 -- 1998 ' Eurocode 3 ' Eurocode 3: Design of steel structures ' Eurocode3 UK ' ' CHINA GB50017 - 2003 ' Code of Design of Steel Structures , GB-50017-03 ' INDIA IS800-2007 ' Indian Standard, General Construction In Steel -- Code of Practice, Third Edition, IS 800 : 2007 Note: AISC stands for American Institute of Steel Construction. CISC stands for Canadian Institute of Steel Construction.

Round cut dimensions: 1 mm or 5 mm . This applies when the primary dimension " Units " are set to ' Metric '. It sets the rounding method that connection design will apply when setting the lengths and widths of shear plates, bent plates, end plates, auto base/cap plates, stiffener plates, etc.

In a full-featured SDS2 program . . .

'

1 mm ' instructs connection design to round plate lengths and widths up to the nearest millimeter. Canadian users of SDS2 programs may prefer this option.

'

5 mm ' instructs connection design to round plate lengths and widths up to the nearest 5 millimeter increment. This is generally the preferred choice for European users of SDS2 programs.

Design method for moment connections: Elastic or Plastic . This applies when ' ASD9 ' is the " Connection design method ." The other design methods use the plastic moment capacity.

In Modeling in a full-featured SDS2 program . . .

The choice made here affects the calculated design moment applied during connection design of a moment connections when "

Auto " is selected as the " Moment load " on the Beam Edit window. The percentage entered (below) to " Base beam design moment on % of maximum allowable moment " is applied to either the beam's ' Elastic ' or ' Plastic ' moment strength, depending on the choice made here.

Imperial moment load: kip-in or kip-ft . This appears as an option here only when the primary dimension " Units " are set to one of the choices for ' Imperial .. '.

' kip-in ' indicates that kip-in are the units that are used for the " Moment load " on a beam. This also affects the value (and units) that are shown on the Connection Design Calculations Report or Expanded Connection Design Calculations Report .

' kip-ft ' indicates that kip-ft are the units that are used for the " Moment load " on a beam.

Note: 1 kip-ft = 12 kip-in.

Design non-AISC single-plate shear connections: ![]() or

or ![]() . This applies when ' ASD9 ' or ' LRFD3 ' or ' ASD13 ' or ' ASD14 ' or ' LRFD13 ' or ' LRFD14 ' is the " Connection design method ." See below for an explanation of design method dependencies.

. This applies when ' ASD9 ' or ' LRFD3 ' or ' ASD13 ' or ' ASD14 ' or ' LRFD13 ' or ' LRFD14 ' is the " Connection design method ." See below for an explanation of design method dependencies.

If this box is checked (

), the design check for this maximum thickness is turned off so that connection design will not fail shear plates that are thicker than this. A special Search for Non-AISC Single-Plate Shear Connections can be used to get a list of all beams with non-AISC single-plate shear connections. From this list, you can open individual Beam Review windows.

If this box is not checked (

), connection design applies the AISC design check and fails single-plate shear connections that do not meet it.

" Connection design method " dependencies: For ' ASD9 ' or ' LRFD3 ': A single-plate shear connection's maximum plate thickness is half the bolt diameter plus 1/16 of an inch ( LRFD, Third Edition , pg. 10-113). For ' ASD13 ' or ' LRFD13 ' or ' ASD14 ' or ' LRFD14 ' (conventional configuration): A single-plate shear connection's maximum plate thickness or the maximum thickness of the supported beam's web is permitted to be half the bolt diameter plus 1/16 of an inch ( AISC Thirteenth Edition , p10-102, item 6 under Dimensional Limitations ). For ' ASD13 ' or ' LRFD13 ' (extended configuration), refer to AISC Thirteenth Edition , pg. 10-103, item 2 under Design Checks . For ' ASD14 ' or ' LRFD14 ' (extended configuration), refer to AISC Fourteenth Edition , pg. 10-104, item 2 under Design Checks .

Note: Regardless of whether this box is checked or not checked, during connection design of single-plate shear connections, the program will look to the Single-Plate Shear Connection Schedule of Minimums in order to determine the thickness of plate to be applied in the design of that connection. If the thickness on the schedule is greater than that allowed by AISC, then a plate of that thickness is designed only if this option is checked.

Design non-AISC welds for single plate shear connections: ![]() or

or ![]() . AISC's ASD 9th Edition and LRFD Third Edition specify that, for steel with a yield strength ( Fy value) of 36 ksi, the weld size must be at least 75% of the shear plate thickness. For the 13th and 14th edition AISC manuals, this restriction was changed to 5/8 of the plate thickness for yield strengths of 36 ksi or 50 ksi.

. AISC's ASD 9th Edition and LRFD Third Edition specify that, for steel with a yield strength ( Fy value) of 36 ksi, the weld size must be at least 75% of the shear plate thickness. For the 13th and 14th edition AISC manuals, this restriction was changed to 5/8 of the plate thickness for yield strengths of 36 ksi or 50 ksi.

If this box is checked (

), connection design disregards the above-described specifications and generates a weld size based on the " Shear load " only.

If the box is not checked (

), connection design applies the above-described AISC specification to the design of single-plate shear connections. Which specification applies depends on the AISC " Connection design method " that is selected. This option does not apply to non-AISC connection design methods.

Page numbers in AISC manuals:

9th Edition (ASD): 4-55

3rd Edition (LRFD): 10-223

13th Edition: 10-101

14th Edition: 10-102

Design non-AISC single angle connections: ![]() or

or ![]() . This applies when the " Connection design method " is ' ASD14 ' or ' LRFD14 ' or ' ASD13 ' or ' LRFD13 ' or ' ASD 9 ' or ' LRFD 3 '. It applies to the design of single-angle connections (" Side " = ' Near side ' or ' Far side ').

. This applies when the " Connection design method " is ' ASD14 ' or ' LRFD14 ' or ' ASD13 ' or ' LRFD13 ' or ' ASD 9 ' or ' LRFD 3 '. It applies to the design of single-angle connections (" Side " = ' Near side ' or ' Far side ').

| Page 10-133 of the AISC 14th Edition stipulates the following: | |||||||||

|

|||||||||

If this box is checked (

), then connection design will allow angles with a minimum thickness of 1/4 inch to be designed for a bolt diameter when such an angle has been specified in the Single Clip Angles Bolted OSL or All-Bolted, Single Angle or Single Clip Angles Welded OSL clip angle configuration.. This also permits 5/16 inch angles to be used.

If the box is not checked (

), then connection design will use the minimum thicknesses that are listed on page 10-133 of the AISC 14th Edition manual. A single-angle connection that uses 1/4 inch or 5/16 inch angles can fail with the message: " Angle thickness less than minimum required by AISC ."

Design non-AISC end plate thickness: ![]() or

or ![]() . This applies when the " Connection design method " is ' ASD14 ' or ' LRFD14 ' or ' ASD13 ' or ' LRFD13 ' or ' ASD 9 ' or ' LRFD 3 '.

. This applies when the " Connection design method " is ' ASD14 ' or ' LRFD14 ' or ' ASD13 ' or ' LRFD13 ' or ' ASD 9 ' or ' LRFD 3 '.

In a full-featured SDS2 program ...

If this box is checked (

), then connection design will not apply the AISC maximum thickness limit to a non-moment end plate. Per ASD 9th, the maximum thickness for a shear end plate is 3/8 inch (page 4-4). For all other AISC connection design methods, the maximum is 5/8 inch.

If the box is not checked (

), then connection design will apply the AISC maximum thickness limit to a non-moment end plate. For end plates subjected to high loads, the connection failure message " End plate thickness is greater than maximum " may result.

Always provide stabilizer plates: ![]() or

or ![]() . This applies when ' ASD14 ' or ' LRFD14 ' is the " Connection design method ." Per the "Requirement for Stabilizer Plates" specified on page 10-105 of the AISC 14th Edition , "stabilizing plates are not required when the required shear strength, Ru or Ra, respectively, is equal to or less than the available strength to resist lateral displacement ...."

. This applies when ' ASD14 ' or ' LRFD14 ' is the " Connection design method ." Per the "Requirement for Stabilizer Plates" specified on page 10-105 of the AISC 14th Edition , "stabilizing plates are not required when the required shear strength, Ru or Ra, respectively, is equal to or less than the available strength to resist lateral displacement ...."

|

|

If this box is checked (

), connection design in a full-featured SDS2 program will always provide stabilizer plates for extended single-plate connections, even if they are not required to resist lateral displacement of the beam.

If the box is not checked (

), connection design (in a full-featured SDS2 program) wiill design the connection without stabilizer plates when stabilizer plates are not required.

Also see: Stabilizer plates may be designed for shear ' Plate ' connections to a column web when the option to "

Extend past flange " is checked.

Design non-CISC welds on rolled edges: ![]() or

or ![]() . This applies when ' CISC8 ' or ' CISC9 ' is the " Connection design method ."

. This applies when ' CISC8 ' or ' CISC9 ' is the " Connection design method ."

If this box is checked (

), connection design in a full-featured SDS2 program determines the maximum fillet weld size on a rolled edge as if it were a sheared edge. See page 6-172 of the CISC Ninth Edition .

If the box is not checked (

), connection design (in a full-featured SDS2 program) uses the rule "Effective size = D - 1/4 when D = t" to set the maximum fillet weld size on a rolled edge. See page 6-173 of the CISC Ninth Edition .

Design non-CISC end plate thickness: ![]() or

or ![]() . This applies when ' CISC 8 ' or ' CISC 9 ' or ' CISC 10 ' is the " Connection design method ." It applies to shear end plates (non-moment end plates).

. This applies when ' CISC 8 ' or ' CISC 9 ' or ' CISC 10 ' is the " Connection design method ." It applies to shear end plates (non-moment end plates).

| Page 3-66 of the CISC 10th Edition suggests the following: | ||

|

||

If this box is checked (

), connection design in a full-featured SDS2 program disregards the above-quoted suggestion and will, if needed, design a shear end plate that is thicker than 10 mm. For end plates that exceed the 10 mm thickness limitation, the Connection Design Calculations Report and the Expanded Connection Design Calculations Report will feature a call for additional engineering review such as the following: "Connections with Fy > 248 MPa, or more than 12 bolt rows, or bolt dia. > 26 mm, or thickness > 10 mm require engineering investigation."

If the box is not checked (

), connection design will not design an end plate that is thicker than 10 mm. Consequently, the connection may fail with a message such as " End plate thickness is greater than maximum ."

Use alternate weld pattern for single sided clip angle: ![]() or

or ![]() . This applies when ' CISC 8 ' or ' CISC 9 ' or ' CISC 10 ' or ' CISC 11 ' is the " Connection design method ."

. This applies when ' CISC 8 ' or ' CISC 9 ' or ' CISC 10 ' or ' CISC 11 ' is the " Connection design method ."

|

|

If this box is checked (

), connection design uses a weld pattern like that shown in Fig. 10-13 (c), p10-132, AISC Fourteenth Edition, where the weld return on the top of the angle is per Section J2.2b, which requires that the length of a weld be at least the thickness of the connecting material.

If the box is not checked (

), connection design uses a weld pattern like that shown on p 3- 69 in Table 3-40 of the CISC Tenth Edition, where the weld runs along the full width of the top edge of the angle leg that welds to supporting member.

Use alternate eccentricity for extended shear tabs: ![]() or

or ![]() . This applies when ' ASD13 ' or ' LRFD13 ' or ' ASD14 ' or ' LRFD14 ' is the " Connection design method ." It applies to "

. This applies when ' ASD13 ' or ' LRFD13 ' or ' ASD14 ' or ' LRFD14 ' is the " Connection design method ." It applies to " ![]() Extend past flange " shear connections. Per the AISC 13th Edition , p 10-103 and AISC 14th Edition , p 10-104, "Alternate considerations of the design eccentricity are acceptable when justified by rational analysis. For example, see Sherman and Ghorbanpoor (2002)."

Extend past flange " shear connections. Per the AISC 13th Edition , p 10-103 and AISC 14th Edition , p 10-104, "Alternate considerations of the design eccentricity are acceptable when justified by rational analysis. For example, see Sherman and Ghorbanpoor (2002)."

|

The two connection design calculation reports notify you when the alternate eccentricity calculation has been used. |

If this box is checked (

) and ' Automatic ' is selected for " Use alternate eccentricity ," then connection design in a full-featured SDS2 program uses the alternate method prescribed by Sherman and Ghorbanpoor (2002) for calculating eccentricity. In the Connection Design Calculations report or Expanded Calculations report, you will get a note that the " Alternate eccentricity calculation has been used " or that the " Alternate eccentricity calculation is not applicable to this connection ."

If this box is not checked (

) and ' Automatic ' is selected for " Use alternate eccentricity ," connection design (n a full-featured SDS2 program) uses the standard method for calculating eccentricity.

Allow 8 mm welds on 9.5 mm (3/8 inch) thick material: ![]() or

or ![]() . This applies when ' CISC 8 ' or ' CISC 9 ' or ' CISC 10 ' or ' CISC 11 ' is the " Connection design method ."

. This applies when ' CISC 8 ' or ' CISC 9 ' or ' CISC 10 ' or ' CISC 11 ' is the " Connection design method ."

|

CISC Tenth Edition,

p 6-172 |

||

If this box is checked (

), a maximum weld size of 8 mm is permitted for welding a material whose thickness is 9.5 mm (3/8 inch).

If the box is not checked (

), the maximum fillet weld size permitted for welding 9.5 mm thick material is 7 mm ( t - 2 ) per the CISC recommendation quoted above.

Always base shear tab design on flexible support condition: ![]() or

or ![]() .

.

If this box is checked (

), single-plate shear connections are designed on a "flexible" support, which is a more conservative design assumption than a "rigid" support.

If the box is not checked (

), connection design automatically determines the support condition. To determine the support condition, connection design will use the "Definition of Rigid support" found under "Connection Design Notes" in the Connection Calculation Cover Sheet (#7 for ASD , #8 for LRFD ).

home > project settings > job > design > | classic | top

|

|

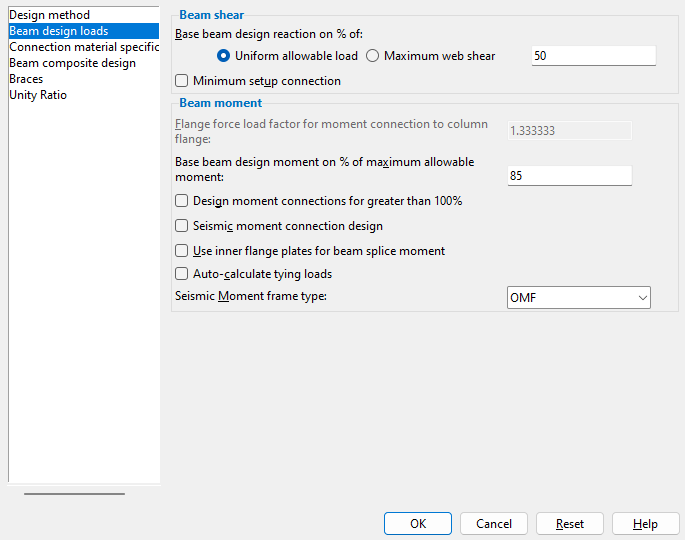

------ Beam shear------

Base beam design reaction on % of: Uniform allowable load or Maximum web shear and a percentage .

In a full-featured SDS2 program . . .

First select whether you want connection design to calculate the ' Uniform allowable load ' or the ' Maximum web shear '. Then enter the ' percentage ' you want connection design to multiply this amount by. Connection design uses the selected method and the percentage entered to calculate the design reaction at each end of a beam. This reaction is calculated from the section size properties. The design reaction, in turn, determines the strength of the connection and the "

Auto " " Shear load " reported on the Beam Edit window.

Example: To " Beam design reaction ," you select ' Uniform Allowable Load ' and enter a percentage of ' 60 '. For a W18x 50, steel grade A572-50, 28 ft span beam, connection design calculates a uniform allowable load of 70 kips. It multiplies this total load by 60% and enters the resulting value of 42 kips as the "

Auto " " Shear load " on the Beam Edit window.

From the Connection Calculations Cover Sheet: The uniform allowable load is the distributed load which causes a simply supported beam of the same length as the member to yield in flexure at the beam's midspan. The maximum web shear is calculated in accordance with Section G2.1 ( ASD or LRFD ) or Clause 5.11 ( AS 4100 ) or Clause 13.4.1.1 ( CISC ).

Minimum setup connection: ![]() or

or ![]() . This applies when ' Automatic ' is selected for " Minimum setup connection " under "

. This applies when ' Automatic ' is selected for " Minimum setup connection " under " ![]() Connection type " on the Beam Review window or Horizontal Brace Review window or Vertical Brace Review window.

Connection type " on the Beam Review window or Horizontal Brace Review window or Vertical Brace Review window.

When " Minimum setup connection " is ' Automatic ' in a full-featured SDS2 program . . .

If this box is checked (

), connection design uses a minimal value for the loads that are set to "

Auto " and thus creates a connection on that end of the member with the minimum number of bolt rows, the minimum plate thickness, etc. In the "

Loads " leaf of any affected Beam/Brace Edit window, a green banner notifies you that the connection has been designed with the " Minimum setup connection capacity ."

If the box is not checked (

), connection design calculates "

Auto " loads based on entries made to " Base beam design reaction on " (for beam connections) or " Base beam design moment on " (for moment connections) or " Percent of allowable tension load " (for brace connections) or " Percent of allowable compression load " (for brace connections).

Reports: The Connection Design Calculations Report and Expanded Connection Design Calculations Report provide the connection strength for various limit states in either case.

------ Beam moment ------

Flange force load factor for moment connection to column flange: A factor from 1 to 2 . Refer to AISC specification K1.2 in the Manual of Steel Construction, Allowable Stress Design, 9th Edition . This only applies when ' ASD9 ' is the selected " Connection design method ."

Base beam design moment on % of maximum allowable moment: A percentage from 5 to 200 percent. The percentage is used to calculate the " ![]() Auto " " Moment load ." Moment capacity is calculated in accordance with Section F2.1 ( ASD or LRFD ) or Clause 5.2 ( AS 4100 ) or Clause 13.5 ( CISC ).

Auto " " Moment load ." Moment capacity is calculated in accordance with Section F2.1 ( ASD or LRFD ) or Clause 5.2 ( AS 4100 ) or Clause 13.5 ( CISC ).

In a full-featured SDS2 program . . .

To " Beam design moment . . . " (this field), you enter a percentage of ' 80 '. For a particular section of a particular steel grade used as the " Section size " for a particular beam, connection design uses the " Moment of inertia " reported in the local shape file , takes into consideration whether the ' Plastic ' or ' Elastic ' " Design method " is used, and calculates a maximum allowable moment of 1000 kip-in. It multiplies this calculated maximum by 80% and enters the resulting value of 800 kip-in as the "

Auto " " Moment load " on the Beam Edit window for that beam.

Design moment connections for greater than 100%: ![]() or

or ![]() . This applies to welded beam to column flange moment connections or to a bolted moment end plate to a wide flange column flange. Only the "column side" is designed for the larger moment.

. This applies to welded beam to column flange moment connections or to a bolted moment end plate to a wide flange column flange. Only the "column side" is designed for the larger moment.

In a full-featured SDS2 program . . .

If this box is checked (

), connection design creates a welded or end plate moment connection when the "

Auto " " Moment load " on the Beam Edit window is greater than 100% of the maximum allowable moment (a maximum of 125% is allowed). This does not apply to a user-entered " Moment load ." For a particular moment connection that has been designed for a load exceeding 100% of the allowable, the Connection Design Calculations Report or Expanded Connection Design Calculations Report states, " Warning -- The design moment exceeds the beam moment capacity. "

If this box is not checked (

), connection design fails moment connections when the "

Auto " " Moment load " (or a user-entered " Moment load ") is greater than 100% of the beam moment capacity.

Seismic moment connection design: ![]() or

or ![]() . A beam-to-column-flange seismic moment connection can be designed in a full-featured SDS2 program when " Seismic moment frame member " is set to ' Yes ' or, possibly, to ' Automatic ' and " Seismic moment frame type " is set to ' OMF ' or ' IMF ' or ' SMF ' or, possibly, to ' Automatic ' and the left- or right-end " Moment type " is ' Bolted ' or ' Welded '. ' SMF ' or ' IMF ' seismic moment connections can be designed when the " Connection design method " is any LRFD edition. ' OMF ' seismic moment connections can be designed for LRFD and ASD editions.

. A beam-to-column-flange seismic moment connection can be designed in a full-featured SDS2 program when " Seismic moment frame member " is set to ' Yes ' or, possibly, to ' Automatic ' and " Seismic moment frame type " is set to ' OMF ' or ' IMF ' or ' SMF ' or, possibly, to ' Automatic ' and the left- or right-end " Moment type " is ' Bolted ' or ' Welded '. ' SMF ' or ' IMF ' seismic moment connections can be designed when the " Connection design method " is any LRFD edition. ' OMF ' seismic moment connections can be designed for LRFD and ASD editions.

In a full-featured SDS2 program . . .

If this box is checked (

), then each beam in your current Job that has " Seismic moment frame member " set to ' Automatic ' will automatically get the same connection design results that you would get if that same option on those same beams had been set to ' Yes '.

If this box is not checked (

), you will get connection design results that are equivalent to setting " Seismic moment frame member " to ' No '.

Seismic moment connection design: ![]() or

or ![]() . A beam-to-column-flange seismic moment connection can be designed when " Seismic moment frame member " is set to ' Yes ' or, possibly, to ' Automatic ' and " Seismic moment frame type " is set to ' OMF ' or ' IMF ' or ' SMF ' or, possibly, to ' Automatic ' and the left- or right-end " Moment type " is ' Bolted ' or ' Welded '. ' SMF ' or ' IMF ' seismic moment connections can be designed when the " Connection design method " is any LRFD edition. ' OMF ' seismic moment connections can be designed for LRFD and ASD editions.

. A beam-to-column-flange seismic moment connection can be designed when " Seismic moment frame member " is set to ' Yes ' or, possibly, to ' Automatic ' and " Seismic moment frame type " is set to ' OMF ' or ' IMF ' or ' SMF ' or, possibly, to ' Automatic ' and the left- or right-end " Moment type " is ' Bolted ' or ' Welded '. ' SMF ' or ' IMF ' seismic moment connections can be designed when the " Connection design method " is any LRFD edition. ' OMF ' seismic moment connections can be designed for LRFD and ASD editions.

In a full-featured SDS2 program, when " Seismic moment frame member " is ' Automatic ' on the Beam window . . .

If this box is checked (

), then each beam in your current Job that has " Seismic moment frame member " set to ' Automatic ' will automatically get the same connection design results that you would get if that same option on those same beams had been set to ' Yes '.

If this box is not checked (

), you will get connection design results that are equivalent to setting " Seismic moment frame member " to ' No '.

Use inner flange plates for beam splice moment: ![]() or

or ![]() .

.

|

|

|

If this box is checked (

) and ' Automatic ' is selected for " Use inner flange plates ," connection design in a full-featured SDS2 program incorporates inner flange plates into the design of the bolted moment beam splice connection. A total of four inner flange plates may be designed: 1) an upper NS inner flange plate, 2) an upper FS inner flange plate, 3) a lower NS inner flange plate and 4) a lower FS inner flange plate.

If this box is not checked (

) and ' Automatic ' is selected for " Use inner flange plates ," a full-featured SDS2 program incorporates only outside moment flange plates into the design of the connection.

Auto-calculate tying loads: ![]() or

or ![]() . This affects whether or not the " Tye force " on the Beam Review window is checked (

. This affects whether or not the " Tye force " on the Beam Review window is checked ( ![]() ) or not checked (

) or not checked ( ![]() ) by default. For auto calculation of the tye force to take place, the " Connection design method " can be set to any LRFD or ASD edition. The magnitude of the auto calculated tying load is equal to the shear load for ASD, to 2/3 shear load for LRFD.

) by default. For auto calculation of the tye force to take place, the " Connection design method " can be set to any LRFD or ASD edition. The magnitude of the auto calculated tying load is equal to the shear load for ASD, to 2/3 shear load for LRFD.

In a full-featured SDS2 program . . .

If this box is checked (

), then when a new beam is added, its " Tye force " is calculated automatically. That is, the box for "

Tye force " is checked on the Beam Edit window.

If the box is not checked (

) and you subsequently check the box for "

Tye force " on a beam's edit window, the force will will be set to ' 0 '.

Seismic moment frame type: OMF or IMF or SMF . This applies when ' Automatic ' is selected for " Seismic moment frame type " under " ![]() Seismic " on the Beam Edit window.

Seismic " on the Beam Edit window.

In a full-featured SDS2 program, when " Seismic moment frame type " is ' Automatic ' . . .

' OMF ' instructs connection design to use "Ordinary Moment Frame" design. This design code is only recommended for non-seismic or low seismic regions since such frames provide less resistance to lateral motion than do IMF or SMF seismic moment resisting frames.

' IMF ' instructs connection design to use "Intermediate Moment Frame" design. IMF seismic moment resisting frames should only be installed in moderate seismic regions.

' SMF ' stands for "Special Moment Frame" design code for seismic moment connections. SMF seismic moment resisting frames are designed to resist flexural, axial, and shearing actions that result as a building sways through multiple inelastic displacement cycles due to a strong earthquake.

home > project settings > job > design > | classic | top

|

|

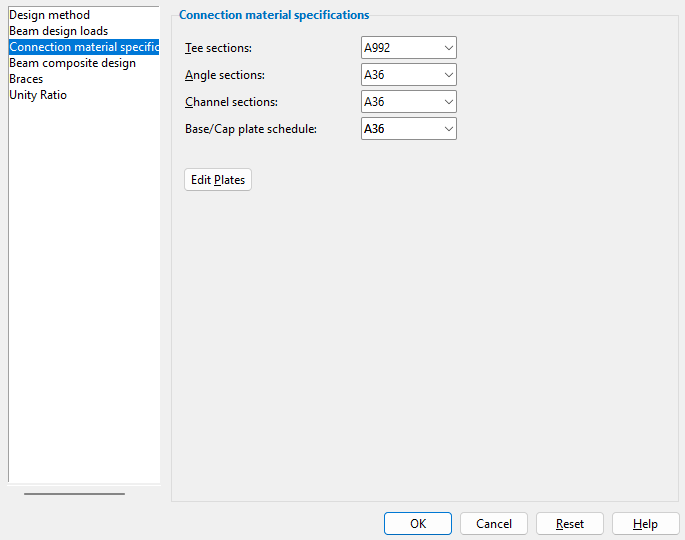

Tee sections: Any steel grade in the WT Grades list may be specified here.

Effect on a full-featured SDS2 program: The steel grade that is selected here applies to tee connection materials on system connections in your current Job. For example, it applies to the connection design of tee seats and tee shear connections in a full-featured SDS2 program .

Also see: The Standard Fabricator Connections table Preferred WT Sizes lists tee sections that can be used by connection design for the creation of tee seats and tee shear connections.

Angle sections: Any steel grade listed in Angle Grades may be specified here.

Effect on a full-featured SDS2 program: The steel grade that is selected here applies to angle connection materials on system connections in your current Job. For example, it applies to the connection design of clip angles in a full-featured SDS2 program .

Also see: The Standard Fabricator Connections table Preferred Angle Sizes lists angle sections that can be used by connection design for angle seats, bolted angle moment connections and offset beam-to-beam framing.

Channel sections: Any steel grade listed in Channe Grades may be specified here.

Effect on a full-featured SDS2 program: The steel grade that is selected here applies to channel connection materials on system connections in your current Job. For instance, this grade is used for the design of channel splices in a full-featured SDS2 program .

Also see: Fabricator Setup > Standard Fabricator Connections > Splice Plate Setup lists channel sections that can be used by connection design for column splices.

Base / Cap Plate Schedule: Any steel grade listed in Plate Grades may be specified here.

Effect on a full-featured SDS2 program: This steel grade applies to plate definitions for which ' Default (xxx) ' is selected on the list box (

) for the " Steel Grade " column on the Base / Cap Plate Schedule .

Opens the same Preferred Plates Sizes window that is also found in Standard Fabricator Connections :

|

|

this button is not found in Site Planning |

home > project settings > job > design > | classic | top

|

|

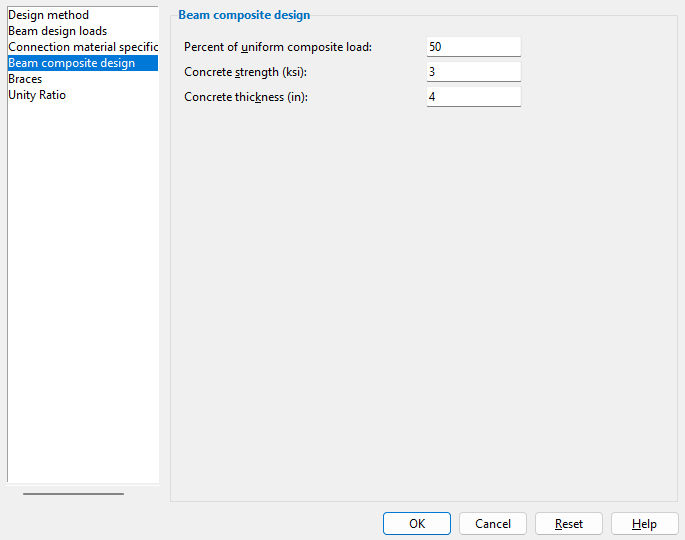

Percent of uniform composite load: A percentage . A beam composite section is any beam with the " Composite Design " option checked ( ![]() ). A composite beam is typically able to carry a stronger load than a noncomposite beam. Two different methods may be used to calculate the " Shear load " for a composite beam. These are:

). A composite beam is typically able to carry a stronger load than a noncomposite beam. Two different methods may be used to calculate the " Shear load " for a composite beam. These are:

Method 1: Multiply the calculated shear load for a non-composite section by an Rx factor entered to the " Composite Reaction Factor Schedule ."

Method 2: If ' 1 ' is entered on the " Composite Reaction Factor Schedule " for a beam of a particular nominal depth, connection design calculates the uniform composite load for that beam based on that beam's section properties and the " Concrete strength " and " Concrete thickness ." To calculate the " Shear load " for each end of the composite beam, the program will multiply the percentage entered here by the calculated uniform composite load.

Concrete strength (ksi or MPa): A value in the primary dimension " Units " being used ( kips/sq. inch or MPa ).

Effect on a full-featured SDS2 program: The concrete strength shown here is used to calculate the uniform composite load for beams with the box for " Composite design " checked if that beam has a nominal depth for which an " Rx factor " of ' 1 ' is entered on the " Composite Reaction Factor Schedule ."

Concrete thickness: The concrete thickness (in the primary dimension distance " Units ").

Effect on a full-featured SDS2 program: The concrete thickness shown here will be used to calculate the uniform composite load for beams with the box for " Composite design " checked if that beam's " Section size " has a nominal depth for which an " Rx factor " of ' 1 ' is entered on the " Composite Reaction Factor Schedule ."

home > project settings > job > design > | classic | top

|

|

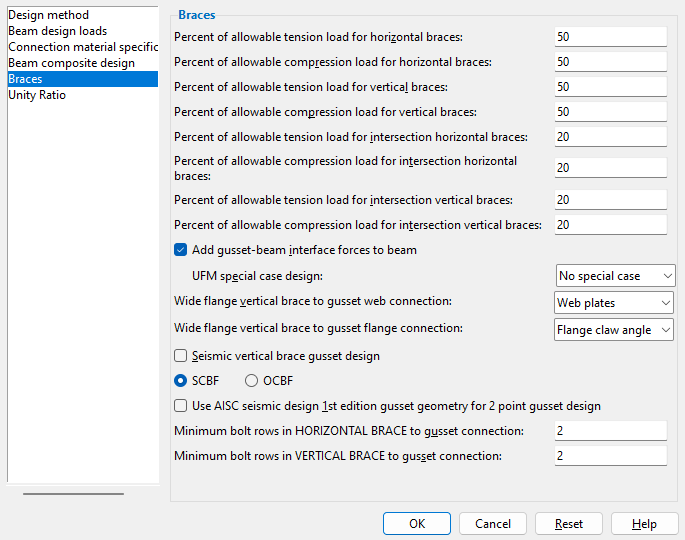

Percent of allowable tension load for horizontal braces: A value of up to 100 percent of the brace's gross tension capacity calculated in accordance with Section D2 ( ASD or LRFD ) or Clause 7.2 ( AS 4100 ) or Clause 13.2 ( CISC ).

Connection design uses the ' percentage ' entered here to calculate the left/right "

Auto " " Tension load " on a horizontal brace's edit window.

Percent of allowable compression load for horizontal braces: A value of up to 100 percent of the brace's compression load capacity calculated in accordance with Section E3 ( ASD or LRFD ) or Clause 6.3 ( AS 4100 ) or Clause 13.3 ( CISC ).

Connection design uses the ' percentage ' entered here to calculate the left/right "

Auto " " Compression load " on a horizontal brace's edit window.

Percent of allowable tension load for vertical braces: A value of up to 100 percent of the brace's gross tension capacity calculated in accordance with Section D2 ( ASD or LRFD ) or Clause 7.2 ( AS 4100 ) or Clause 13.2 ( CISC ).

Connection design uses the ' percentage ' entered here to calculate the left/right "

Auto " " Tension load " on a vertical brace's edit window.

Percent of allowable compression load for vertical braces: A value of up to 100 percent of the brace's compression load capacity calculated in accordance with Section E3 ( ASD or LRFD ) or Clause 6.3 ( AS 4100 ) or Clause 13.3 ( CISC ).

Connection design uses the ' percentage ' entered here to calculate the left/right "

Auto " " Compression load " on a vertical brace's edit window.

Percent of allowable tension load for intersection horizontal braces: A value of up to 100 percent of the allowable tension load of the intersected horizontal brace. This value is applied to the intersecting brace, if it is single-sided.

|

The intersecting horizontal brace is the brace that frames to the intersected brace. |

In a full-featured SDS2 program . . .

A single sided intersection brace can act as a support for the intersected brace. Consequently, connection design uses the ' percentage ' entered here to calculate -- from the intersected brace's gross tension load capacity -- the left/right "

Auto " " Tension load " on the intersecting horizontal brace's edit window.

Percent of allowable compression load for intersection horizontal braces: A value of up to 100 percent of the allowable compression load of the intersected horizontal brace. This value is applied to the intersecting brace, if it is single sided.

The intersecting horizontal brace is the brace that frames to the intersected brace. In a full-featured SDS2 program . . .

A single sided intersection brace can act as a support for the intersected brace. Consequently, connection design uses the ' percentage ' entered here to calculate -- from the intersected brace's gross tension load capacity -- the left/right "

Auto " " Compression load " on the intersecting vertical brace's edit window.

Percent of allowable tension load for intersection vertical braces: A value of up to 100 percent of the allowable tension load of the intersected vertical brace. This value is applied to the intersecting brace, if it is single-sided.

The intersecting vertical brace is the brace that frames to the intersected brace. In a full-featured SDS2 program . . .

A single sided intersection brace can act as a support for the intersected brace. Consequently, connection design uses the ' percentage ' entered here to calculate -- from the intersected brace's gross tension load capacity -- the left/right "

Auto " " Tension load " on the intersecting vertical brace's edit window.

Percent of allowable compression load for intersection vertical braces: A value of up to 100 percent of the allowable compression load of the intersected vertical brace. This value is applied to the intersecting brace, if it is single sided.

|

A single-sided intersecting vertical brace can act as a support for the intersected brace. |

In a full-featured SDS2 program . . .

A single sided intersection brace can act as a support for the intersected brace. Consequently, connection design uses the ' percentage ' entered here to calculate -- from the intersected brace's gross tension load capacity -- the left/right "

Auto " " Compression load " on the intersecting vertical brace's edit window.

Add gusset-beam interface forces to beam: ![]() or

or ![]() . This applies when a vertical brace frames to a beam and column. In such a framing situation, the Uniform Force Method of design transfers brace forces into the beam connection. This field gives users of a full-featured SDS2 program the option of applying those forces to the design of the beam connection.

. This applies when a vertical brace frames to a beam and column. In such a framing situation, the Uniform Force Method of design transfers brace forces into the beam connection. This field gives users of a full-featured SDS2 program the option of applying those forces to the design of the beam connection.

|

|

|

||||

|

|

If this box is checked (

), connection design in a full-featured SDS2 program adds the gusset-beam forces to the beam. The loads are reported on the Beam Review window along with the other " Load " information and are automatically used (along with the other loads) during the design of the beam end connection. For the beam connection, the Connection Design Calculations Report (or Expanded Calculations ) states that "These forces have NOW been automaically included."

If the box is not checked (

), the gusset-beam interface forces are not automatically incorporated into the design of the beam end connection. The Connection Design Calculations Report and Expanded Connection Design Calculations Report for the beam connection note the magnitude of these forces and warn that they "have not been automatically included."

UFM special case design: No special case or Special case 2 or Special case 3 . This applies when ' Automatic ' is selected for " UFM special case design " on the Vertical Brace Review window under " ![]() Connection specifications ."

Connection specifications ."

|

|

|

When ' No special case ' is selected and " UFM special case design " is set to ' Automatic ', connection design in a full-featured SDS2 program is instructed to distribute the brace's vertical force to the beam as well as to the gusset-to-column connection. This minimizes the size of the gusset plate, but may result in the beam connection failing under heavily loaded conditions. See The Uniform Force Method , AISC 14th Edition , p 13-3.

When ' Special case 2 ' is selected and " UFM special case design " is set to ' Automatic ', connection design (in a full-featured SDS2 program ) is instructed to distribute the brace's vertical force to the gusset-to-column connection instead of to the beam. As a result, the beam's vertical reaction is not increased. This may prevent the beam connection from failing if the beam is highly loaded, but also may add rows to the column connection and thus cause the gusset plate to be larger. See Special Case 2 , Minimizing Shear in the Beam-to-Column Connection , AISC 14th Edition , p 13-7.

When ' Special case 3 ' is selected and " UFM special case design " is set to ' Automatic ', connection design is instructed to connect the vertical brace to the beam, but not to the column. See Special Case 3, No Gusset-to-Column Web Connection , AISC 14th Edition , p 13-7. Be aware that special case 3 does not apply to gusset-to-column flange connections. For gusset-to-column flange connections, the connection will be designed as if ' No special case ' has been selected.

Wide flange vertical brace gusset web connection: None or Web plates or Channels . This applies when ' Standard connection ' is selected as the " Connection arrangement " for a wide flange vertical brace whose " Web orientation " is ' Vertical ' and when ' Automatic ' is selected for " Web connection type " ( ![]() ) under "

) under " ![]() Connection specifications " on the Vertical Brace Review window or at Home > Project Settings > Job > User Defined Connections :

Connection specifications " on the Vertical Brace Review window or at Home > Project Settings > Job > User Defined Connections :

|

|

When " Web connection type " is ' Automatic ' in a full-featured SDS2 program . . .

' None ' can get you an automatic connection when the " Wide flange vertical brace gusset flange connection " (below) is set to ' Flange claw angles '. That connection will consist of flange claw angles without a web connection.

' Web plates ' can get you an automatic connection when the " Wide flange vertical brace gusset flange connection " (below) is set to ' Flange claw angles ' or to ' None '. The NS and FS web plates will connect the web of the web-vertical wide flange vertical brace to the gusset plate.

' Channels ' can get you an automatic connection when the " Wide flange vertical brace gusset flange connection " (below) is set to ' None '. A channel web connection consists of NS and FS channels that connect the web-vertical wide flange vertical brace to the gusset plate.

Permitted configurations: 1) Web plates only. 2) Web channels only. 3) Web plates with flange angles. 4) Flange angles only.

Not permitted: Channels with claw angles cannot be designed. Instead of a connection, you get the failure message " Incompatible web and flange connection types ."

Wide flange vertical brace gusset flange connection: None or Flange claw angles . This applies when ' Standard connection ' is selected as the " Connection arrangement " for a wide flange vertical brace whose " Web orientation " is ' Vertical ' and when ' Automatic ' is selected for " Flange connection type " ( ![]() ) under "

) under " ![]() Connection specifications " on the Vertical Brace Review window or at Home > Project Settings > Job > User Defined Connections .

Connection specifications " on the Vertical Brace Review window or at Home > Project Settings > Job > User Defined Connections .

|

|||||||||

| The left and middle brace connections have the same " Tension load ." The flange-angles-only connection (on the right) has a smaller " Tension load ." |

When " Flange connection type ' is ' Automatic ' in a full-featured SDS2 program . . .

' None ' specifies that connection design attempt to design a ' Standard connection ' that does not use claw angles

' Flange claw angles ' instructs connection design to design a ' Standard connection ' that uses claw angles to connect the wide flange vertical brace's flanges to the gusset plate. The shape of the gusset is adjusted to permit the flange angles to fit.

Permitted configurations: 1) Web plates only. 2) Web channels only. 3) Web plates with flange angles. 4) Flange angles only.

Not permitted: Channels with claw angles cannot be designed. Instead of a connection, you get the end connection failure message " Incompatible web and flange connection types ."

Seismic vertical brace gusset design: ![]() or

or ![]() . A seismic vertical brace can be designed for any vertical brace framing situation , so long as the brace is a valid material type .

. A seismic vertical brace can be designed for any vertical brace framing situation , so long as the brace is a valid material type .

|

|

||||

| In the left example, one construction line is drawn along the end of the brace. The other passes through the corner of the gusset. The same construction lines are in the right example. | |||||

When " Seismic brace " is ' Automatic ' in a full-featured SDS2 program . . .

If this box is checked (

), connection design is instructed to create a seismic connection on both ends of the brace. If "

Auto " is selected for the vertical brace's " Tension load " and/or " Compression load ," connection design creates a connection with seismic loading on that end of the vertical brace. If "

Auto " is not selected for " Tension " and/or " Compression " load, connection design still creates a seismic gusset plate if ' SCBF ' is selected. For HSS rectangular/TS seismic braces, connection design provides reinforcement plates.

If the box is not checked (

), connection design creates a non-seismic connection. The gusset not be designed with a hinge zone, and the end of the brace will be the " Brace to other member " distance from the supporting member.

Steel grade setup for seismic design "

Auto" loads:

Factors controlling " Auto " load calculation for seismic design

(per section I-6 of the AISC Seismic Design Manual )Steel grade setup Tensile strength Yield strength wide flange Rt Ry angle Rt Ry channel Rt Ry welded plate W Rt Ry HSS rectangular / TS Rt Ry round bar Rt Ry W tee Rt Ry HSS round / pipe Rt Ry

' ![]() SCBF ' or '

SCBF ' or ' ![]() OCBF ': This applies to vertical braces when " Seismic brace " is set to ' Yes ' (or to ' Automatic ' with "

OCBF ': This applies to vertical braces when " Seismic brace " is set to ' Yes ' (or to ' Automatic ' with " ![]() Seismic vertical brace gusset design " checked on).

Seismic vertical brace gusset design " checked on).

| The same user tension load was applied to all three of these examples . | |||||||||||

|

|

|

|||||||||

|

The left and right gusset plates are the same. Only the middle gusset is unique. If the applied load for all of these examples was an " |

|||||||||||

'

SCBF ' instructs connection design in a full-featured SDS2 program to use the " Multiplication factor... " set in Plate Design Settings to determine the distance parallel with the workline of the brace from the end of the brace (or paddle plate or built-up tee) to the nearest corner of the gusset. SCBF stands for Special Concentrically Braced Frame.

'

OCBF ' instructs a full-featured SDS2 program to design the gusset plate based on the applied load, without consideration of the " Multiplication factor '. OCBF stands for Oridinary Concentrically Braced Frame. As you can see from the examples above, an ' OCBF ' seismic gusset plate is the same as a non-seismic gusset plate when the brace connection has been designed using the same non-auto " Tension load " and/or " Compression load ." For a gusset plate designed for an auto load, a seismic ' OCBF ' brace would be substantially larger than an equivalent non-seismic brace since the caclulated auto load would be larger for the seismic brace.

Use AISC seismic design 1st edition for 2 point gusset design: ![]() or

or ![]() . This applies (in a full-featured SDS2 program ) to the design of 2-point vertical brace gusset plates when " Seismic brace " is set to ' Yes ' (or to ' Automatic ' with "

. This applies (in a full-featured SDS2 program ) to the design of 2-point vertical brace gusset plates when " Seismic brace " is set to ' Yes ' (or to ' Automatic ' with " ![]() Seismic vertical brace gusset design " checked on). It controls what happens when " AISC seismic 1st ed. 2pt gussets " under "

Seismic vertical brace gusset design " checked on). It controls what happens when " AISC seismic 1st ed. 2pt gussets " under " ![]() Connection specifications " on the Vertical Brace window is set to ' Automatic '.

Connection specifications " on the Vertical Brace window is set to ' Automatic '.

|

||

| The 1st edition AISC seismic design manual specifies more cuts for 2-point gusset plates than does later editions of that same manual. |

If this box is checked (

) and ' Automatic ' is selected for " AISC seismic 1st ed. 2pt gussets " on the Vertical Brace window, connection design (in a full-featured SDS2 program) is instructed to design a 2-point seismic gusset that is based on the 1st edition of the AISC seismic design manual.

If the box is not checked (

) and ' Automatic ' is selected for " AISC seismic 1st ed. 2pt gussets " on the Vertical Brace window, connection design is instructed to design a 2-point seismic gusset that is based on the 2nd edition of the AISC seismic design manual.

M inimum bolt rows in horizontal brace to gusset connection: The minimum number ( 1 or 2 or 3 , etc.) of rows of bolts that you want to be allowed for connecting a horizontal brace to its gusset plate. If needed, connection design will increase the number of bolt rows in order to create a connection that will stand up to the load. By default, the minimum is set to ' 2 '.

minimum = 1

|

minimum = 2

|

minimum = 3

|

M inimum bolt rows in vertical brace to gusset connection: The minimum number ( 1 or 2 or 3 , etc.) of rows of bolts that you want to be allowed for connecting a vertical brace to its gusset plate. If needed, connection design will increase the number of bolt rows in order to create a connection that will stand up to the load. By default, the minimum is set to ' 2 '. This option does not apply to " HSS erection bolts ."

minimum = 2

|

minimum = 3  |

home > project settings > job > design > | classic | top

|

|

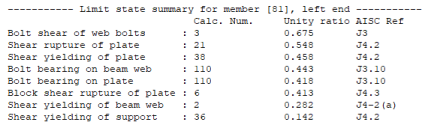

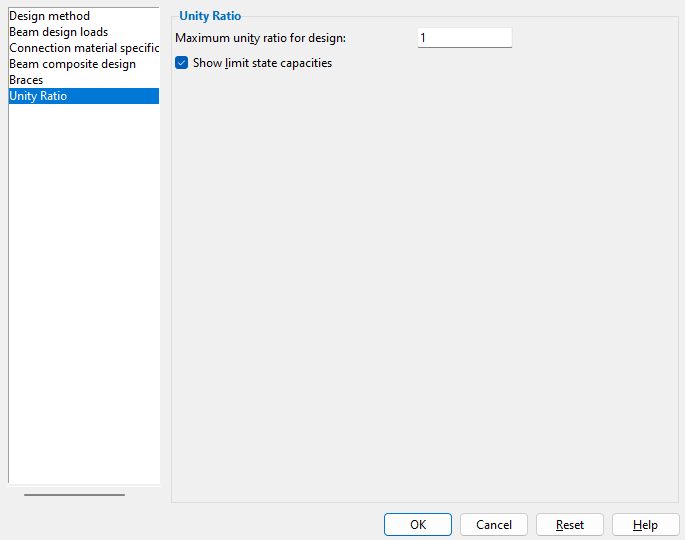

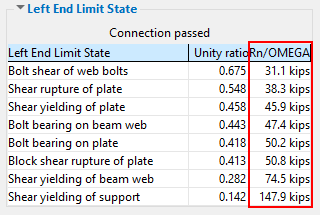

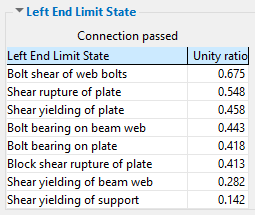

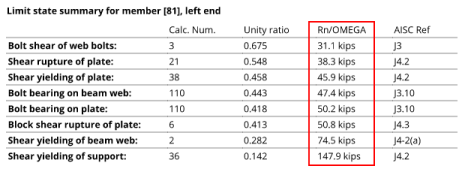

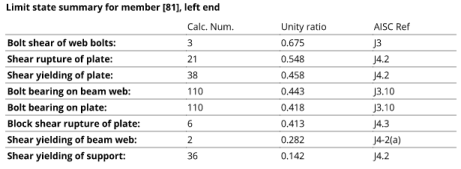

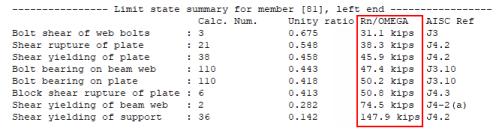

Maximum unity ratio for design: The maximum Unity Ratio value instructs connection design in a full-featured SDS2 program. The default value is 1.0.

Show limit state capacities:

![]() or

or ![]() . This applies when Maximum unity ratio for design is set to 1.0. Showing limit state capacities is not valid if the Maximum unity ratio for design does not equal 1.0. When Maximum unity ratio for design is not set to 1.0, this option will be disabled. The limit state capacities will not be shown in member edit windows, Expanded Calculations, and Design (shorter) Calculations reports.

. This applies when Maximum unity ratio for design is set to 1.0. Showing limit state capacities is not valid if the Maximum unity ratio for design does not equal 1.0. When Maximum unity ratio for design is not set to 1.0, this option will be disabled. The limit state capacities will not be shown in member edit windows, Expanded Calculations, and Design (shorter) Calculations reports.

If this box is checked (

), and Maximum unity ratio for design is set to 1.0, limit state capacities are shown in member edit windows, Expanded Calculations reports, and Design (shorter) Calculations reports.

If the box is not checked (

), limit state capacities are not shown in member edit windows, Expanded Calculations reports, and Design (shorter) Calculations reports.

Show limit state capacities

(Member Edit)

Show limit state capacities

(Member Edit)

Show limit state capacities

(Expanded Calculations)

Show limit state capacities

(Expanded Calculations)

Show limit state capacities

(Design (short) Calculations)

Show limit state capacities

(Design (short) Calculations)