Leveling Plate

Leveling Plate

This tool must be downloaded from SDS2 Toolbox and installed in order to use it.

- General Overview

- Step-By-Step

- Tips and Tricks

- Related Tools

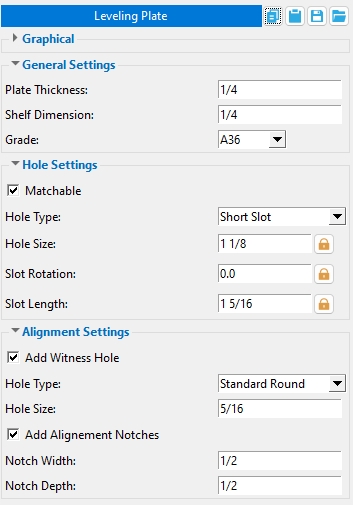

General Settings

Plate Thickness: The Thickness of the Leveling Plate being added/edited.

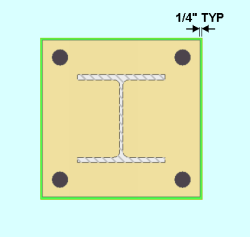

Shelf Dimension: The overhang of the Leveling Plate relative to the base plate (see example below, where Shelf Dimension = 1/4"). This controls the overall size of the Leveling Plate. It allows you to add to every side of the plate, using the base plate as a reference. You can also enter a negative dimension to make the Leveling Plate smaller than the base plate.

Grade: This is the grade of steel for the Leveling Plate whose settings are defined on this window.

Setup: If the grade of steel you want is not shown in the list box (

), you can use Home > Project Settings > Job > Material Grades > Plate Grades to add it to this list.

Hole Settings

Matchable:

![]() or

or ![]() . If this box is checked (

. If this box is checked ( ![]() ) and the hole(s) are in a material that is face-to-face with the base plate material, the Model > Hole > Match to match the hole(s) to a different material.

) and the hole(s) are in a material that is face-to-face with the base plate material, the Model > Hole > Match to match the hole(s) to a different material.

If the box is not checked (

), the hole(s) will not be matched to other material during Model > Hole > Match or during the matching holes phase of Create Solids.

Note: Certain Hole types are, by default, set to not matchable (

Matchable).

Hole Type: Choose Standard round or Short slot or Oversized round or Long slot or Cope hole or Erection pin hole or Anchor bolt hole or Plug weld hole or Grout or User slot #1 or User slot #2 or Vent/Drain.

A Standard round hole is perfectly round and has a Hole diameter that is typically 1/16 inch larger than the Bolt diameter.

A Short slot hole is oblong in shape and has a relatively short Slot length (1 5/16 inch for a 1 inch diameter bolt).

An Oversized hole will typically input a Hole diameter 3/16 inch larger than the Bolt diameter.

A Long slot hole is oblong in shape, has a diameter 1/16 inch larger than the input bolt diameter, and has a relatively long Slot length (2 1/2 inch for a 1 inch diameter bolt).

A Cope hole is for using a punch or drilling machine instead of a cutting machine to cope a piece of material. By default, cope holes are not matchable (

Matchable ).

An Erection pin hole is a hole on the end of a column for use by a crane to lift the column into place (see show erection pin holes on columns ). By default, erection pin holes are set to be not matchable (

Matchable ).

An Anchor bolt hole is a hole for anchor bolts in a column base plate. Holes must be of this type in order for them to be automatically dimensioned when the Dimension anchor bolt layout option is selected during erection view regeneration. By default, anchor bolt holes are not matchable (

Matchable ).

A Plug weld hole is for adding to a material before the material is plug welded . By default, plug weld holes are not matchable (

Matchable ).

A Grout hole may be used for pouring grout under a base plate. By default, vent/drain holes are not matchable (

Matchable ).

User slot #1 and User slot #2 are slots whose Slot length are set, based on the Bolt diameter, from user-entered length settings maintained at Home > Project Settings > Job > User Slot Lengths .

Hole Size: A system-calculated or user-entered distance that will be the diameter of the hole(s) modeled in the Leveling Plate.

Slot Rotation: A positive or negative number from 90 to -90 degrees. This applies when the Hole type is Long slot or Short slot. Slot rotations can be modeled to a precision of 0.1 degree.

Slot Length: The system-calculated or user-entered distance between the two points farthest from one another on the perimeter of a slot.

Alignment Settings

Add Witness Hole: ![]() or

or ![]() . A witness hole can be added to see when the plate is flush with the concrete.

. A witness hole can be added to see when the plate is flush with the concrete.

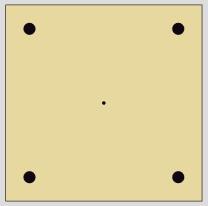

If this box is checked (

), a hole is added to the center of the plate.

If this box is not checked (

), a witness hole is not added.

Hole Type: Standard round or Oversized round or Cope hole or Erection pin hole or Anchor bolt hole or Plug weld hole or Grout or Vent/Drain. For a more thorough explanation of each of these types, see Hole type on the Hole Edit window.

Hole Size: The diameter of the hole added to the plate if Add Witness Hole is checked.

Add Alignment Notches: ![]() or

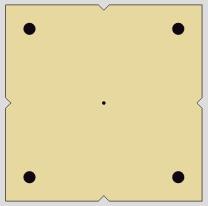

or ![]() . V-notches can be added to all four sides of the leveling plate at the column X & Y centerlines to help align the leveling plates with field lines.

. V-notches can be added to all four sides of the leveling plate at the column X & Y centerlines to help align the leveling plates with field lines.

If this box is checked (

), notches are added and aligned with the X & Y centerlines of the column.

If this box is not checked (

), notches are not added to the leveling plate.

Notch Width: The width of the notch measured along the outside edge of the leveling plate.

Notch Depth: The depth of the notch measured from the outside edge to the center of the leveling plate.

![]() Copy, Paste, Save, Load buttons:

Copy, Paste, Save, Load buttons:

1 . Click the Add Component icon. The icon can be found on the Material page > Dynamic Components section. Select Leveling Plate.

Method 2: Preselect a Column member to enable the Members contextual page and click the Add Component icon found in the Materials/Components section. Select Leveling Plate. Skip step 2.

Alternative: Invoke Leveling Plate using the Find Tool by searching the command name and clicking the icon, which is pictured above.

Learn more about alternative methods for launching commands.

2 . The status line prompts, " Locate member to add to " and Select One Item mouse bindings become active. Select the column that you wish to add the leveling plate to, then press the Enter key or right-click and choose OK on the context menu.

3 . The Leveling Plate Edit window opens. The settings in this window are filled out with default settings or the settings that match the last leveling plate that you added or edited in your current Modeling session. Press the "OK" button when you are done with the settings in this window.

Alternative: Press the Esc key or right-click and choose Cancel to not add the member to a group member.