The Turned Solid/Shell Element window ( Modeling ) (read-only)

- To open this window:

- Review Material ( Modeling )

- "Review Other" on context menu, select material mark ( Modeling )

- Double-click on material -- not main material ( Modeling )

- Review 2D Items ( Drawing Editor )

Also see :

- General Information window (can be opened from this window)

- Submaterial piecemark (each unique material identified by)

- Submaterial detail (2D drawing of a material)

page 1 | contents | material review | material types

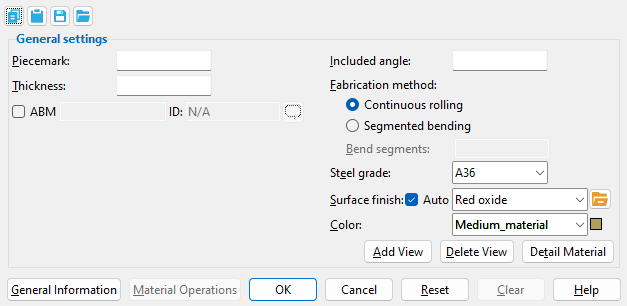

------ General settings ------

Piecemark: The submaterial piecemark ( up to 61 characters ) for the turned solid/shell element whose settings you are reviewing.

Also see: The submaterial piecemarking prefix for " Miscellaneous items " is used when assigning piecemarks to turned solid/shell element. For the current quantity of turned solid/shell elements that have been assigned this piecemark, see " Current quantity " on this material's General Information window.

Thickness: The wall thickness (in the primary dimension " Units " or in other units ) of the turned shell element. This field does not apply to turned solid elements.

Included angle: The number of degrees of turning applied to the turned element.

Fabrication method: Continuous rolling or Segmented bending .

' Continuous rolling ' results in the turned solid/shell element being generated with a smooth, continuous surface.

' Segmented bending ' requires that you specify a number of " Bend segments ."

Bend segments: The number (6 or 7 or 8 or ...) of bend segments used when ' Continuous rolling ' is the " Fabrication method ."

Steel grade: Any grade of steel ( A36 or A572 or etc.) from the Job Options setup table for Plate Grades & Bar Stock may be shown here as the steel grade for this material.

Surface finish: None or Sandblasted or Red oxide or Yellow zinc or Gray oxide or Blued steel or Galvanized or Duplex Coating or Undefined 1 or Undefined 2 or Undefined 3 or Red oxide 2 or Any user added surface finish. This affects the colors of 'Solid ' members on erection views in the Drawing Editor . This also sets the color when "Output material color " is set to 'Surface finish ' for a VRML Export or a DWG/DXF Export . The "Color " ( not "Surface finish ") sets the color of this material in Modeling .

| sand blasted | red oxide | yellow zinc | user surface finish 1 |

| gray oxide | blued steel | galvanized | user surface finish 2 |

To assign a different surface finish, you can drop-down the current surface finish and select the one you want, or you can press the "file cabinet" browse button (

) and double-click any surface finish that is on the list.

Auto ![]() or

or ![]() .

.

If this box is checked (

), the material surface finish follows what is set on the member level.

If the box is not checked (

), the material surface finish can be changed to whatever is available in the list of surface finishes. If the surface finish changes from what the member level has set, the auto checkbox will be unchecked automatically. When the auto check box is unchecked, the member edit window shows an information tag which notifies the user that an attached material is not following what was set on the member level.

Note 1: Submaterial piecemarks can be split apart by surface finish. All surface finishes that do not have the 'Break Marks Material' checked on can be applied to any like material with out the material splitting. If the 'Break Marks Material' is checked on then only like materials with that specific surface finish can have the same piecemark, and because the submaterial marks differ so would the member's piecemark.

Note 2:When exporting a KISS file using "model" as the "Data source " surface finish data on the materials are compiled into the KISS download as follows, with a few exceptions (G=galvanized, N= none or sandblasted, P= others). Those exceptions are:

If the box for "Finish" routing in KISS export setup is set to a user routing

If the user has adjusted the Abbreviation for any of the default provided surface finishes

If you are using a user added surface finish

In these cases you will get what is provided in either the User routing, or the abbreviation field. For other exports it will always provide the abbreviation in the 'surface finishes' settings page.

Tip 1: "Surface area" is reported on the General Information window -- and this can be used to estimate the amount of coating required and its cost.

Tip 2: Changing "Steel grade " "Color " and "Surface finish " do not cause the plate to be regenerated. This means that, if you change those settings only, material fit operations such as a Fit Exact may, optionally, be preserved.

Report Writer:MemberMaterial.Material.SurfaceFinish

Setup:Surface Finish Settings

Color: The color of the turned solid/shell element when it is displayed in solids form . Different colors may be assigned to materials that have the same submaterial piecemark . The color swatch next to the list box ( ![]() ) displays the color that is selected.

) displays the color that is selected.

Setup: The default colors for member main materials and submaterials is set up on the Modeling Colors setup window.

page 1 | contents | material review | material types | top

To close this window :

" General Information " opens the General Information window, which you can use to review additional information about the selected material.

Press " Close " on the General Information window to close that window and reactivate this window.

"OK" (or the Enter key) closes this window.

page 1 | contents | material review | material types | top