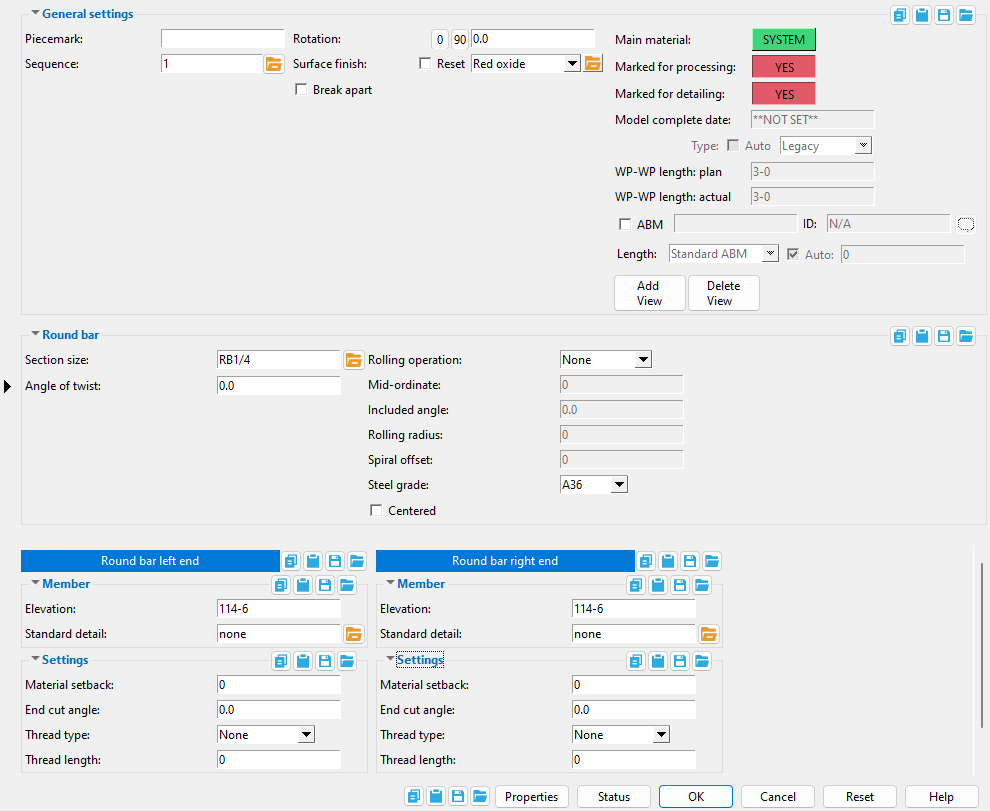

Round Bar Edit window

( Modeling > F2 > "  Misc steel " > " Round Bar ")

Misc steel " > " Round Bar ")

Selecting " Round Bar " as the "  Miscellaneous steel " type adds a custom member with round bar material to a 3D model.

Miscellaneous steel " type adds a custom member with round bar material to a 3D model.

The Round Bar custom member is a superior alternative to " Miscellaneous -- Round Bar ." The edit window of this member features material and member options on the same window.

Its " General settings " include " Break apart " and " Rotation ," which are not available for the legacy miscellaneous member.

Member operations such as many of those found on the Model > Member menu in Modeling can be performed on this member, and you can add custom components to it.

- To open this window:

- Add Round Bar (documentation is on this page)

- Double-click (any submaterial of the Round Bar with ' Default ' as the filter)

- Edit Member

- Edit by Piecemark (alternative to Edit Member )

- Edit by Member Number (alternative to Edit Member )

- Selection filter (useful tool that aids selection)

The " OK " button is disabled (grayed out) to indicate a validation error. Hover the " OK " button with your mouse pointer to get a listing of settings you need to change on this window. When all settings are valid, the " OK " button is enabled.

Red-colored highlighting identifies an entry that is invalid. You need to change that setting, or you will not be able to close this window using " OK ." Also see :

- Round Bar (topic)

- Miscellaneous member types (the complete list)

- Custom members (a round bar miscellaneous member is a custom member)

- Round Bar Material (window can set Round Bar Edit's " Main Material " to ' USER ')

- Miscellaneous members versus legacy miscellaneous members (topic)

page 1 | contents | add (F2) | top

Add round bar :

1 . A round bar miscellaneous member can be properly located and rotated even in an isometric view. Before adding the member, be aware of the following:

2 . To add a round bar miscellaneous member (in Modeling ):

Alternative 1 : Press F2 > check the box for "

Miscellaneous steel " > double-click " Round Bar ."

Alternative 2 : Choose Model > Member > Prompt for Member Type > check the box for "

Miscellaneous steel " > double-click " Round Bar ."

3 . Locate - Repeat - Return mouse bindings become active, and you are prompted to locate the round bar's work points. Two work points are required to lay out round bar.

bindings 3a : Select the appropriate Locate option.

3b : Left-click ( Locate ) at two different on-screen positions to define the member line between those two points. The first work point you enter when you add the round bar defines the left end of the member. Both points are represented as exact points after step 4, when the member is actually generated in the model.

The work points of a round bar align with one of its edges, or, if " Centered " is checked (

), with its center.

The first point that you locate is identified by an origin symbol . The origin symbol also tells you which end is the member's left end. The following illustration shows the difference between locating the two points from left to right versus right to left.

If you Model > Member > Isolate > ... a round bar miscellaneous member, you will find that the member's MAIN VIEW shows the member's origin symbol (

) to be to your left. This is true for any miscellaneous member -- even if the origin symbol for the member is to your right in a plan view. The MAIN VIEW in member isolation directly correlates to the main view of the miscellaneous member's detail.

Best practice when adding a miscellaneous member in a plan view is to input the member from left to right or from bottom to top. That way, when you add a grid line from left to right, the near side of the member, as determined by the location of its left end , will be the side looking toward the bottom or toward the right of the screen.

4 . After you are done laying out work points, the Round Bar Edit window opens. On it are settings of the round bar you are adding.

3a : Enter a " Section size ." This sets the bar diameter.

3b : Choose whether you want the round bar to be " Centered " or not.

3c ( optional ): The " Left/right end settings " on this window let you specify cuts or material setbacks on the ends of the round bar. The left end is the end associated with the first point you located in step 3.

3d : Press the " OK " button at the bottom of the window to apply your settings and exit this window.

Note: The default settings on this window are those of the last round bar miscellaneous member added or edited in this session of Modeling . Even if all you do is double-click a round bar member and press " OK " on its edit window, its settings become the defaults for the next-added round bar miscellaneous member. You therefore only need to make changes to those settings which are different for this member.

5 . If User and Site Options > Modeling > " Process after modeling operation " is ' Process and create solids ', the new plate will have automatically undergone all phases of Process and Create Solids and will show up in a solid form . If that option is ' Process ' or ' Do nothing ', then the member line of the round bar you just added shows up on screen in stick form , and you will have to Process > Process and Create Solids in order to have the member piecemarked and able to be displayed in a solid form. Do one (1) of the following:

bindings Alternative 1 : Move the mouse pointer (

) and middle-click ( Repeat ) to lay out a round bar just like the last one beginning at the point where the point location target (

) is at. The X, Y global axes location of the repeated bar will begin from the located repeat point (where the target is at). The plate's Z location and other settings will be that of the last-added or last-edited round bar.

Alternative 2 : Follow these instructions beginning with step 3 to add a round bar with different settings than the one you just laid out.

Alternative 3 : Right-click ( Return ) if you are done adding round bar.

page 1 | contents | add (F2) | top

------ Round bar ------

Section size: any round bar " Section size " that is maintained in the local shape file . You must enter a section size in order to add round bar .

The " Section size " that is entered sets the rod diameter of the round bar. To enter a section size: You can type in the section size that you want, or you can press the "file cabinet" browse button (

) and double-click a section size from the list that opens. The list includes only the section sizes that are in the local shape file . The usual convention for entering a section size is described here . Validation prevents you from entering a section size that does not exist in the local shape file.

Angle of twist: 0 (zero) degrees or the positive or negative (-) number of degrees of twist about the member line of the round bar.

' 0 ' results in the member's main material not being twisted.

Entering a ' number of degrees ' causes the left end of the member's main material to remain fixed, while its right end is rotated the number of degrees entered.

The following can be used to track the choice made here when " Main material " is ' SYSTEM ':

Report Writer: XXXXX . MaterialTwistAngle

Advanced Selection: MaterialTwistAngle

Parametric module: MaterialTwistAngleRolling operation: None or Camber or Weak axis or Strong axis . The center of curvature for each of these choices (except ' None ') is midway between the left and right ends of the round bar.

None

Camber

Weak axis

Strong axis

' None ' makes the round bar straight (not curved).

' Camber ' produces parabolic bending along the strong axis of the round bar with the ends fixed. The " Mid-ordinate " sets the offset at mid-span and the direction (+ or -) of that offset.

' Weak axis ' or ' Strong axis ' rolling produces bending that is circular. The two ends of the round bar are not fixed; that is, if the ends were vertical before the operation, they may not be vertical afterwards. The " Mid-ordinate " or " Included Angle " or " Rolling radius " sets the offset at mid-span and the direction (+ or -) of that offset. Optional: You can, in addition, apply a " Spiral offset ."

The following can be used to show the choice made here when " Main material " is ' SYSTEM ':

Report Writer: XXXXX . RollTypeDescription

Mid-ordinate: The positive or negative (-) distance (in the primary dimension " Units " or other units ) that the round bar is offset at mid-span as a result of a " Rolling operation " of ' Camber ' or ' Strong Axis ' or ' Weak Axis '. The sign (+ or -) sets the direction of offset.

Camber with a positive mid-ordinate ( +m )

Camber with a negative mid-ordinate ( -m )

Weak axis rolling with a positive mid-ordinate

( rolling toward the near side )

Weak axis rolling with a negative mid-ordinate

( rolling toward the far side )

Strong axis rolling with a positive mid-ordinate ( +m )

Strong axis rolling with a negative mid-ordinate ( -m )

The following can track the choice made here when " Main material " is ' SYSTEM ':

Report Writer: XXXXX . MidOrdinate

Included angle: The positive or negative (-) number of degrees that sets the angle of curvature when the " Rolling operation " is ' Strong axis ' or ' Weak axis '.

i = included angle. Extrapolate a circle from the inside curvature of the member's main material, then draw a line along each end of the material. The lines will meet at the center of the imaginary circle, and their included angle is the angle entered here. If the left end of the round bar is to your left: A ' negative (-) angle ' lowers the center of the round bar's curvature on your computer screen. A ' positive angle ' makes the center of the member's curvature lower on your computer screen than its two ends.

The following can be used to track the choice made here when " Main material " is ' SYSTEM ':

Report Writer: XXXXX . IncludedAngle

Advanced Selection: IncludedAngle

Parametric module: IncludedAngleRolling radius: A positive or negative (-) distance (in the primary dimension " Units " or other units -- up to +/- 120,000 inches) that defines the amount of curvature of the round bar when the " Rolling operation " is ' Strong axis ' or ' Weak axis '. The smaller the " Rolling radius " (+ or -), the greater the curvature. This option applies if if the entries to both the " Mid-ordinate " and " Included angle " are ' 0 '.

r = rolling radius. If you were to extrapolate a circle from the inside curvature of the member's main material, the distance from any point on the inside curve of the top/bottom flange to the center of the circle is the distance entered here. If the left end (work point 1)of the round bar is to your left: A ' positive rolling radius ' raises the center of the round bar's curvature on your computer screen. A ' negative (-) rolling radius ' makes the center of the round bar's curvature lower on your computer screen than its two ends.

The following can be used to show the choice made here when " Main material " is ' SYSTEM ':

Report Writer: XXXXX . RollingRadius

Advanced Selection: RollingRadius

Parametric module: RollingRadiusSpiral offset: The positive or negative (-) distance (in the primary dimension " Units " or other units ) that you want the right end of the round bar to be offset from work point 2. The left end (work point 1) of the round bar remains fixed. This applies when the " Rolling operation " is ' Weak axis ' or ' Strong axis ', and a non-zero entry has been made to the " Mid-ordinate ," " Included angle ," or the " Rolling Radius " fields.

For a round bar whose member line is in the work plane of a plan view: A ' positive distance ' raises the right end. A ' negative (-) distance ' lowers the right end.

The following can be used to show the choice made here when " Main material " is ' SYSTEM ':

Report Writer: XXXXX . SpiralOffset

Advanced Selection: SpiralOffset

Parametric module: SpiralOffsetSteel grade: A36 or A572 or etc. This is the grade of steel for the round bar whose settings are defined on this window.

Setup: If the steel grade you want is not on the list box (

) for this field, you can use Home > Project Settings > Job > Round and Square Bar Grades to add it to the list.

Tip: Changing the " Steel grade " does not cause the round bar to be regenerated. This means that, if you change this setting only, material cut operations such as a Cut Layout may, optionally, be preserved.

The following can be used to track the choice made here when " Main material " is ' SYSTEM ':

Report Writer: MemberMaterial.Material.SubMaterial.MaterialGradeDescription

Advanced Selection: MaterialGrade

Parametric module: MaterialGradeCentered:

or

. The choice made here positions the round bar's depth with respect to its member line.

If this box is checked (

), aligns center of the round bar's depth with respect to the round bar's work points.

If the box is not checked (

), the round bar is positioned below its member line, which runs along distance spanned by the bar's member line.

Note: " Centered " does not affect the global coordinates of the round bar's workline; it does change the round bar's position with respect to its workline.

page 1 | contents | add (F2) | top

Round bar left end

Round bar right end

An origin symbol identifies a miscellaneous member's left end when you hover its member line.

------ Member ------

End elevation: The elevation (in the primary dimension " Units " or other units ) of the work point at this end of the round bar. For a non-sloping bar, both the left and right end elevations are the same. When you add the bar, its work points are placed in your current view's reference elevation until you change their elevations here, on this window.

A round bar has two exact points , whose elevation you can change by changing the member's left- and/or right-end " End elevation ."

To determine the end elevation on a round bar in the 3D model , use Construction Line Add or a similar tool, select EXPT as the Locate option, then snap the point location target to the work point at the end of the member. The Z coordinate reported in the X-Y-Z display tells you the elevation at the snapped-to exact point.

Tip: You should use this option instead of rotating a round bar member's material to change its left- or right-end elevation. For complex situations, you can Model > Member > Move/Stretch one or the other of its work points.

Standard detail: None or a standard detail name . To apply a standard detail, you can type in the file name of the drawing (if you know it), or press the "file cabinet" browse button (

) and double-click any job standard detail or global standard detail that is on the list.

If ' none ' is entered here, then no standard detail will be applied on this end of the miscellaneous member when it is automatically detailed .

If a ' standard detail name ' is entered here, the next time you auto detail this miscellaneous member, the reference point of the standard detail will align with the input work point on this end of the member, and the standard detail's bill of material will be combined with the member's bill of material. The detail is placed on a layer that is named after the standard detail plus a "_L" or "_R" suffix.

page 1 | contents | add (F2) | top

------ Settings ------

Material setback: The positive or negative (-) distance (in the appropriate " Units ") that you want the (left or right) end of the round bar to be displaced from its work point.

A ' positive material setback ' makes the round bar member shorter. The distance is subtracted from the distance spanned by the bar's member line to give you the length of the bar.

A ' negative (-) material setback ' makes the round bar longer. The distance is also subtracted from the distance spanned by the bar's member line to give you the length of the bar.

The following can show the choice made here when " Main material " is ' SYSTEM ':

Report Writer: XXXXX . MaterialSetbackLeftEnd

Report Writer: XXXXX . MaterialSetbackRightEnd

Advanced Selection: MaterialSetback[0] or MaterialSetback[1]

Parametric module: MaterialSetback[0] or MaterialSetback[1]End cut angle: Any angle from 89 to -89 degrees.

If the left end of the round bar is to your left on your computer screen and negative distances along its Y member axis are toward the bottom of the screen: ' 0 ' (zero) square cuts the end. A ' positive angle ' is measured counterclockwise from a perpendicular bisector to the member line. A ' negative (-) angle ' is measured clockwise from a perpendicular bisector to the member line.

The following can be used to track the choice made here when " Main material " is ' SYSTEM ':

Report Writer: XXXXX . WebCutLeftEnd

Report Writer: XXXXX . WebCutRightEnd

Advanced Selection: WebCutEnd[0] or WebCutEnd[1]

Parametric module: WebCutEnd[0] or WebCutEnd[1]Thread type: Left handed or Right handed . The thread length and thread type (handedness) are dimensioned and annotated on the submaterial detail . You will probably want to select a thread type that matches the thread type of a clevis or turnbuckle that this end of the round bar will be screwed into.

The following can read the choice made here when " Main material " is ' SYSTEM ':

Turnbuckle Material: Left thread type and Right thread type

Clevis Material: Thread Type

Connection Design Locks: Brace Connection To Gusset

Report Writer: XXXXX . ThreadTypeLeftEndDescription

Report Writer: XXXXX . ThreadTypeRightEndDescriptionThread length: The distance (in the primary dimension " Units " or other units ) from the left or right end of the member's main material to where you want the threaded area to end. The thread length and thread type (handedness) are dimensioned and annotated on the round bar material's submaterial detail .. The following illustration shows how the Modeling program represents the threaded area when the round bar is displayed in solid opaque form.

tl = thread length

The following can show the choice made here when " Main material " is ' SYSTEM ':

Report Writer: XXXXX . ThreadLengthLeftEnd

Report Writer: XXXXX . ThreadLengthRightEnd