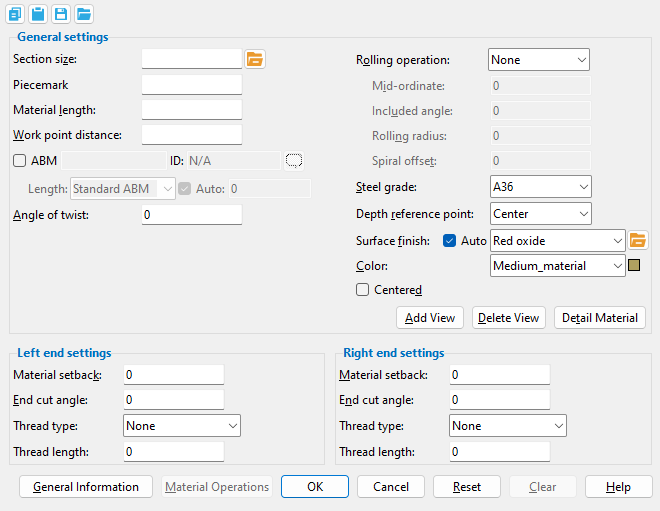

The Round Bar Material window ( Modeling )

- See (on another page): Adding a round bar material or legacy miscellaneous member .

- When a legacy miscellaneous member is first added, Add [Legacy] Miscellaneous Member options are shown on this window.

- To open this window (in Modeling ):

- Add a round bar material or legacy miscellaneous member

- Edit One Material (gives change options)

- Edit Multiple Materials (no change options)

- Double-click the material (to edit a material added using Add Material )

- "Edit Other" (to edit a material added using Add [Legacy] Miscellaneous Member )

- Double-click a material in the Model Tree

- Review 2D Items ( Drawing Editor -- non-editable)

Also see :

- Round bar (topic)

- Round Bar Edit (window for miscellaneous member)

- Miscellaneous members versus legacy miscellaneous members (topic)

- Dimension precision (sets precision for distance entries)

- General Information window (accessible from this window)

- Submaterial piecemark (each unique material identified by)

- Submaterial detail (2D drawing of a material)

- Section size ( Vertical Brace Edit window, may be round bar)

- Add Hole (may be used to add a hole the full length of a round bar)

- Grayed out fields (indicate mixed entries or that the field is disabled)

- Altering a legacy miscellaneous member's main view

" Copy " " Paste " " Save " " Load " buttons :

" Copy " " Paste " " Save " " Load " buttons :

------ General settings ------

| Defaults: If you press " OK " to close this window, the entries made to " Section size ," " Angle of twist ," " Rolling operation ," " Steel grade ," " Centered ," " Surface finish " and " Color " become the defaults for the next-added round bar. |

Section size: any round bar " Section size " that is maintained in the local shape file . You must enter a section size in order to complete an Add Material or Add Legacy Miscellaneous Member operation.

To enter a section size: You can type in the section size that you want, or you can press the "file cabinet" browse button (

) and double-click a section size from the list that opens. The list includes only the section sizes that are in the local shape file . The usual convention for entering a section size is described here . Validation prevents you from entering a section size that does not exist in the local shape file.

Piecemark: Blank or any character string (up to 61 characters). This is the submaterial piecemark .

If this field is left ' blank ', then when this material is generated (after you press " OK "), SDS2 piecemarking looks for materials in the current Job that are physically identical to this material and assigns to this material the same mark assigned to those materials. If no matching materials are found, the material is assigned a piecemark using the appropriate piecemark prefix listed in Home > Project Settings > Fabricator > Member and Material Piecemarking > the " Prefixes " tab.

Any ' character string ' that you enter must be unique. Validation does not let you enter a piecemark that has already been assigned to materials. If you are adding a round bar material or legacy miscellaneous material, a piecemark entered here only applies if the material you are adding is unique -- if the material is exactly the same as previously added materials, the new material gets the piecemark of those previously added materials. On the other hand, if you are editing the material, all materials that are exactly like the material are re-assigned the unique mark you enter when the material is generated (after you press " OK "). The piecemark you enter remains a system piecemark , which means that it may be changed if you later edit a material just like this one and give that material a different piecemark.

Tip: If you want to change a submaterial mark, you should use Rename Project Items in Utility Options . That way all references to the submaterial mark are changed throughout the your current Job, even in Drawing Editor drawings.

Note 1: A submaterial mark is not yet assigned when this window opens for an add material or add legacy miscellaneous member operation. A piecemark is shown when you Edit Material or Review 2D Items . For the current quantity of materials assigned this piecemark, see the " Current quantity " listed on this material's General Information window.

Note 2: Two round bars may have the same submaterial mark , but different submaterial mark index numbers , when any of the following settings are different: " Depth reference point " " Centered " and " Left/Right end settings ."

Report Writer: MemberMaterial.Material.MinorMark

Advanced Selection: MinorMark

Parametric module: MinorMark

Material length: The distance (in the primary dimension " Units " or other units ) from the furthest point on the material's left end to the furthest point on the material's right end. This distance is measured parallel with the material's longitudinal axis ( X material axis ).

Note: Material length entered by the user to this field is added to/subtracted from the end of the round bar opposite to the first point located . For square cut material, the calculated default material length is the work-point-to-work-point length minus any " Material setback (left or right end). Where one end or both ends of the round bar are cut at an angle, the material length may be longer than the " Work point distance ." If you are viewing this window immediately after adding the round bar and you left-clicked ( Locate ) twice at the same point to input a cross section, you will probably want to enter a length to this field instead of using the default.

Report Writer: XXXXX . OrderLength

Advanced Selection: OrderLength or PartLength

Parametric module: OrderLength or PartLength

Work point distance: The distance (in the primary dimension " Units " or other units ) between the work points of this round bar.

Note: The longitudinal axis of the round bar is defined by the two work points of the material. In the material coordinate system, this axis is the X material axis .

Report Writer: XXXXX . WorkpointSlopeDistance

Advanced Selection: WorkpointSlopeDistance

Parametric module: WorkpointSlopeDistance

Angle of twist: 0 (zero) degrees or the positive or negative (-) number of degrees of twist about the longitudinal axis ( X material axis ) of the round bar. The longitudinal axis is the workline defined by the two work points of the material (see step 2 ).

' 0 ' results in the material not being twisted.

Entering a ' number of degrees ' causes the left end (work point 1) of the material to remain fixed, while the right end is rotated the number of degrees entered. Validation accepts entries between -3600 and 3600 degrees and can generate twists to .06 degree. Assuming you are looking from the right end toward the left end of the material, a positive entry rotates the material counterclockwise.

Report Writer: XXXXX . MaterialTwistAngle

Advanced Selection: MaterialTwistAngle

Parametric module: MaterialTwistAngle

Rolling operation: None or Camber or Weak axis or Strong axis . The center of curvature for each of these choices (except ' None ') is midway between the left and right ends of the round bar.

' None '

|

' Camber '

|

' Weak axis '

|

' Strong axis '

|

' None ' makes the round bar straight (not curved).

' Camber ' produces parabolic bending along the strong axis of the round bar with the ends fixed. The " Mid-ordinate " sets the offset at mid-span and the direction (+ or -) of that offset.

' Weak axis ' or ' Strong axis ' rolling produces bending that is circular. The two ends of the round bar are not fixed; that is, if the ends were vertical before the operation, they may not be vertical afterwards. The " Mid-ordinate " or " Included Angle " or " Rolling radius " sets the offset at mid-span and the direction (+ or -) of that offset. Optional: You can, in addition, apply a " Spiral offset ."

Report Writer: XXXXX . RollTypeDescription

Mid-ordinate: The positive or negative (-) distance (in the primary dimension " Units " or other units ) that the round bar is offset at mid-span as a result of a " Rolling operation " of ' Camber ' or ' Strong Axis ' or ' Weak Axis '. The sign (+ or -) sets the direction of offset.

Camber with a positive mid-ordinate ( +m )

|

Camber with a negative mid-ordinate ( -m )

|

| Weak axis rolling with a positive mid-ordinate ( rolling toward the near side )  |

Weak axis rolling with a negative mid-ordinate ( rolling toward the far side )  |

Strong axis rolling with a positive mid-ordinate ( +m )

|

Strong axis rolling with a negative mid-ordinate ( -m )

|

Report Writer: XXXXX . MidOrdinate

Included angle: The positive or negative (-) number of degrees that sets the angle of curvature when the " Rolling operation " is ' Strong axis ' or ' Weak axis '.

If the left end (work point 1) of the round bar is to your left, a ' negative (-) angle ' lowers the center of the round bar on your computer screen. A ' positive angle ' makes the center of the material lower on your computer screen than its two ends.

Report Writer: XXXXX . IncludedAngle

Advanced Selection: IncludedAngle

Parametric module: IncludedAngle

Rolling radius: A positive or negative (-) distance (in the primary dimension " Units " or other units -- up to +/- 120,000 inches) that defines the amount of curvature of the round bar when the " Rolling operation " is ' Strong axis ' or ' Weak axis '. The smaller the " Rolling radius " (+ or -), the greater the curvature.

If the left end (work point 1) of the round bar is to your left, a ' positive rolling radius ' raises the center of the round bar on your computer screen. A ' negative (-) rolling radius ' makes the center of the material lower on your computer screen than its two ends.

Report Writer: XXXXX . RollingRadius

Advanced Selection: RollingRadius

Parametric module: RollingRadius

Spiral offset: The positive or negative (-) distance (in the primary dimension " Units " or other units ) that you want the right end of the round bar to be offset from work point 2. The left end (work point 1) of the round bar remains fixed. This applies when the " Rolling operation " is ' Weak axis ' or ' Strong axis '.

For a round bar whose workline is in the work plane of a plan view:, a ' positive distance ' raises the right end. A ' negative (-) distance ' lowers the right end.

Report Writer: XXXXX . SpiralOffset

Advanced Selection: SpiralOffset

Parametric module: SpiralOffset

Steel grade: A36 or A572 or etc. This is the grade of steel for the round bar whose settings are defined on this window.

Setup: If the steel grade you want is not on the list box (

) for this field, you can use Home > Project Settings > Job > Round and Square Bar Grades to add it to the list.

Tip: Changing " Steel grade " " Color " and " Surface finish " do not cause the round bar to be regenerated. This means that, if you change those settings only, material cut operations such as a Cut Layout may, optionally, be preserved.

Report Writer: MemberMaterial.Material.SubMaterial.MaterialGradeDescription

Advanced Selection: MaterialGrade

Parametric module: MaterialGrade

Depth reference point: Center or FS or NS . ' FS ' stands for far side, ' NS ' for near side. The choice made here positions the round bar's depth with respect to its workline. Assuming that the round bar has not been rotated and was added by locating two points, its depth is parallel to the depth of the view in which the bar was added -- that is, its depth is perpendicular to the plane of that view.

|

|||

| A section view of the same round bar, but with different depth reference points. This view looks perpendicular to the plan view (at 100 ft) in which the round bar was added. |

' Center ' aligns center of the round bar's depth with respect to the round bar's work points.

' FS ' aligns the far side of the round bar with the bar's workline. The far side is the side that is away from you when you are in the view in which the bar was added , assuming the bar was added by locating two different points and was not subsequently rotated. You might select this setting, for example, when your work plane is the Surface of a material, you have located two points on that surface to add this round bar, and you want this bar to be on that surface.

Select ' NS ' if you added the round bar by locating two points at the elevation of a plan view, and you want the rest of the round bar -- everything other than its workline -- to be below the workline's elevation. The near side is the face of the round bar that faces you when you are in the view in which the bar was added , assuming the bar was added by locating two different points and was not subsequently rotated.

Piecemarking: Two round bars, each with a different " Depth reference point ," may have the same submaterial " Piecemark " . The two bars will have different submaterial mark index numbers .

Note: This option does not change the bar's reference elevation. It only changes the positioning of the bar with respect to that reference elevation. You can change a round bar's " Reference elevation " using the General Information window.

Additional examples: Alternative 1 and alternative 2 .

Surface finish: None or Sandblasted or Red oxide or Yellow zinc or Gray oxide or Blued steel or Galvanized or Duplex Coating or Undefined 1 or Undefined 2 or Undefined 3 or Red oxide 2 or Any user added surface finish. This affects the colors of Solid members on erection views in the Drawing Editor . This also sets the color when Output material color is set to Surface finish for a VRML Export or a DWG/DXF Export. The Color (not Surface finish) sets the color of this material in Modeling .

| sand blasted | red oxide | yellow zinc | user surface finish 1 |

| gray oxide | blued steel | galvanized | user surface finish 2 |

To assign a different surface finish, you can drop-down the current surface finish and select the one you want, or you can press the

browse button and double-click any surface finish that is on the list.

Auto ![]() or

or ![]()

If this box

is checked, the material surface finish follows what is set on the member level.

If the box

is not checked, the material surface finish can be changed to whatever is available in the list of surface finishes. If the surface finish changes from what the member level has set, the auto checkbox will be unchecked automatically. When the auto check box is unchecked, the member edit window shows an information tag which notifies the user that an attached material is not following what was set on the member level.

Note 1: Submaterial piecemarks can be split apart by surface finish. All surface finishes that do not have the Break Marks Material checked on can be applied to any like material with out the material splitting. If the Break Marks Material is checked on then only like materials with that specific surface finish can have the same piecemark, and because the submaterial marks differ so would the member's piecemark.

Note 2: When exporting a KISS file using "model" as the Data source surface finish data on the materials are compiled into the KISS download as follows, with a few exceptions (G=galvanized, N= none or sandblasted, P= others). Those exceptions are:

If the box for Finish routing in KISS export setup is set to a user routing

If the user has adjusted the Abbreviation for any of the default provided surface finishes

If you are using a user added surface finish

In these cases you will get what is provided in either the User routing, or the abbreviation field. For other exports it will always provide the abbreviation in the 'surface finishes' settings page.

Tip 1: Surface area is reported on the General Information window -- and this can be used to estimate the amount of coating required and its cost.

Tip 2: Changing Steel grade, Color, and Surface finish do not cause the plate to be regenerated. This means that, if you change those settings only, material fit operations such as a Fit Exact may optionally be preserved.

Report Writer: MemberMaterial.Material.SurfaceFinish

Setup: Surface Finish Settings

Color: A predefined color or a Custom Color . This is the approximate color of the round bar when it is displayed in one of the three solid forms .

The predefined colors are set up on the Predefined Colors window. The color swatch next to the list box (

) displays the color that is selected.

Select Custom Color (last option on the list) to launch your operating system's color picker and define any color you like.

Tip 1: Different colors may be assigned to materials that have the same submaterial piecemark .

Tip 2: Changing " Steel grade " " Color " and " Surface finish " do not cause the round bar to be regenerated. This means that, if you change those settings only, material cut operations such as a Cut Layout may, optionally, be preserved.

Report Writer: MemberMaterial.Material.MaterialColor3dRed

Report Writer: MemberMaterial.Material.MaterialColor3dGreen

Report Writer: MemberMaterial.Material.MaterialColor3dBlue

|

||

| The views shown are the views in which the round bars were added. Note that the origin point in the bottom examples is to the left, whereas in the top examples the origin is on the right. The origin point is the 1st point that was located when the round bar was added. |

If this box is checked (

), the round bar's width will be centered with respect to the round bar's workline. A user-added round bar's workline is established when you add work points . Its near side is the side you are looking at when you add it by locating two points and do not rotate it. When looking at the near side, you see the round bar's length and width, but not its depth.

If the box is not checked (

), the round bar's width is positioned, for example, above or below its workline, which runs along its " Material length ." The workline will be the bottom edge of the round bar if you added the round bar from right to left, are still in the same view, and you did not rotate the bar.

Piecemarking: Two round bars -- one " Centered ," the other not " Centered " -- may have the same submaterial " Piecemark " . The two round bars will have different submaterial mark index numbers .

Note: " Centered " does not affect the global coordinates of the round bar's workline; it does change the round bar's position with respect to its workline. You can change a round bar's " Reference location " (for instance, its elevation) using the General Information window.

Additional examples: Alternative 1 and alternative 2 .

| Special Buttons for Detailing this Material (these do not appear for Add operations) |

||

|

|

|

|

| This button opens a window with a list of preset views . Each preset view that you select on this list is drawn on the submaterial detail when you Detail Submaterial . | This button opens a list of views you can delete. If the material has only one view, you get a warning instead of a list of views since you cannot delete the current view. | This button does a Detail Submaterial on this material. Newly added views are drawn on the detail. Deleted views are not drawn. |

------ Left end settings ------ | ------ Right end settings ------

| This material's left end is the end where the first work point of the material was located. This first work point is also this material's 0,0,0 point in the material coordinate system. The point is identified by the origin reference point symbol at the beginning of a Rotate Material operation. |

Material setback: The positive or negative (-) distance (in the appropriate " Units ") that you want the (left or right) end of the round bar to be displaced from its work point.

A ' positive material setback ' makes the round bar shorter. The distance is subtracted from the " Work point distance " to give you the actual " Material length ."

A ' negative (-) material setback ' makes the round bar longer. The distance is also subtracted from the " Work point distance " to give you the actual " Material length ."

Note: If you make a change here, SDS2 recalculates the " Material length " when you press " OK ." When you open this window again, you will see the results of that recalculation.

Report Writer: XXXXX . MaterialSetbackLeftEnd

Report Writer: XXXXX . MaterialSetbackRightEnd

Advanced Selection: MaterialSetback[0] or MaterialSetback[1]

Parametric module: MaterialSetback[0] or MaterialSetback[1]

End cut angle: Any angle from 89 to -89 degrees. The end cut will be made along the Y material axis (width) of the round bar.

If the left end of the round bar is to your left on your computer screen: ' 0 ' (zero) square cuts the end. A ' positive angle ' is measured counterclockwise from a perpendicular bisector to the workline. A ' negative (-) angle ' is measured clockwise from a perpendicular bisector to the workline.

Report Writer: XXXXX . WebCutLeftEnd

Report Writer: XXXXX . WebCutRightEnd

Advanced Selection: WebCutEnd[0] or WebCutEnd[1]

Parametric module: WebCutEnd[0] or WebCutEnd[1]

Thread type: Left handed or Right handed . The thread length and thread type (handedness) are dimensioned and annotated on the submaterial detail . You will probably want to select a thread type that matches the thread type of a clevis or turnbuckle that this end of the round bar will be screwed into.

Turnbuckle Material: Left thread type and Right thread type

Clevis Material: Thread Type

Connection Design Locks: Brace Connection To Gusset

Report Writer: XXXXX . ThreadTypeLeftEndDescription

Report Writer: XXXXX . ThreadTypeRightEndDescription

Thread length: The distance (in the primary dimension " Units " or other units ) from the left or right end of the material to where you want the threaded area to end. The thread length and thread type (handedness) are dimensioned and annotated on the submaterial detail .. The following illustration shows how the Modeling program represents the threaded area when the round bar is displayed in solid opaque form.

tl = thread length

|

Report Writer: XXXXX . ThreadLengthLeftEnd

Report Writer: XXXXX . ThreadLengthRightEnd

To close this window :

" General Information " opens the General Information window, which provides additional information and settings that pertain to this round bar.

Tip: You can use the General Information window to change the material's " X ," " Y ," or " Z " global coordinates (and thus reposition the material within the 3D model).

Also: A " Properties " button at the bottom of the General Information window lets you Edit Properties for this material.

"OK" (or the Enter key) closes this window and applies the settings on it to the material(s).

Defaults: Even if you did not make any changes to this window, pressing " OK " causes certain " General settings " to be applied as the defaults for the round bar that is added next in your current session of Modeling .

If this window opened for adding a material or legacy miscellaneous member, you can still press " Cancel " on the Rotate Material window to end the add operation (see step 4 ).

If you opened this window to edit a single round bar ( single-edit ), the Change All Options & Warning List opens after you press the " OK " button. You can use that window to cancel your changes or, if other materials with the same submaterial piecemark exist, apply your changes to those other materials. Also, if an Exact Fit or related cutting/bending/fit operation has been done on this round bar, you are given the option to undo that operation.

If you opened this window to edit multiple round bars ( multi-edit ), the Change All Options & Warning List does not open after you press the " OK " button. Also, if an Exact Fit or related cutting/bending/fit operation was previously done on any of those round bars, you are not given the option to undo that operation.

"Cancel" (or the Esc key or the ![]() button) closes this window without saving any changes.

button) closes this window without saving any changes.

Possibilities: If you are adding a new material or a legacy miscellaneous member, " Cancel " brings you back to the work point location step ( step 2 ) in the add operation. For an edit material operation, " Cancel " ends the operation.

Tip: When you open this window to review information only -- and you do not want to set the defaults for the next-added round bar -- the best way to close this window is to press " Cancel. "

"Reset" undoes all changes made to this window since you originally opened it. The window remains open.

Note: The settings shown on this window when it first opens for the adding of a material or legacy miscellaneous member are the settings of the last-added round bar (unless you exit Modeling in the meantime).

"Clear" fills out this window with default settings. These same defaults are applied when the first new round bar is added during a session of Modeling in which no other round bar has been edited. For example, " Clear " automatically selects the default " Steel grade " and zeros out the " Left/Right End Settings ." It also unchecks the box for " Centered ."

Note: The " Clear " button can be used when adding material or a legacy miscellaneous member. It is disabled during an Edit Material operation.